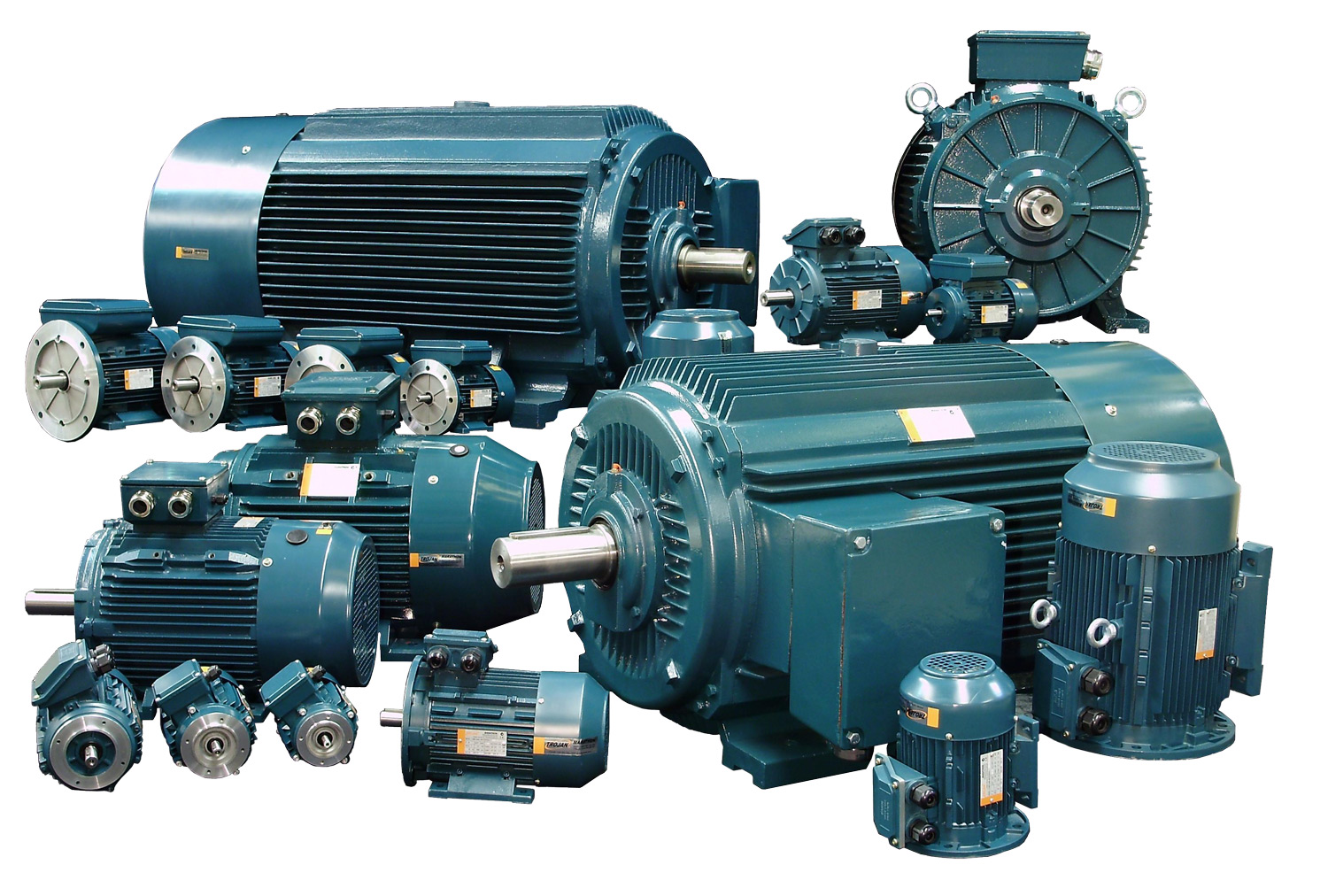

Product Description

YY series single phase capacitor run asynchronous motors,are suitable for fans, blowers, and various equipments requiring light load starting.This series motors with high power factor and efficiency, small size, light weight, good performance, low noise, and convenient maintenance

| Power: | 0.55kw-2.2kw | Voltage: | 220/230V( can can done as your need) |

| Frequency: | 50/60hz | Enamelled Wire: | Copper Wire (Can Done Aluminum wire as Your Need) |

| Insulation Class: | F | Mounting Way: | B3/B5/B14/B34/B35 |

| Protection Grade: | IP54 IP44 | motor body : | cast iron/cast aluminum |

.

1. Are you a manufacturer or trading company?

We are a professional manufacturer of single phase motor,three phase electric motor and pump

2. Where is your factory located?

Our factory is in HangZhou,HangZhou,ZHangZhoug,China. it is very near from HangZhou city,HangZhou city,ZheJiang city.

3. How do you confirm your quality?

A. Rich experience on weakness may appear on every components and products;

B. 100% checking before order and bulk sample reserved in warehouse for after-sale service.

4. Is it acceptable to use self-label brand?

Yes, we provide OEM products, also welcome ODM OTM orders.

5. What is your payment terms?

T/T and L/C. Normally T/T 30% deposit, 70% balance should be paid against the B/L copy.

Better payment terms Available for regular esteemed customers.

6. What is your company’s production capacity every year?

We have over 200,000 pcs production capacity every year.

7. Is sample available for my reference before final order?

Yes, we support trial sample order(1-100pcs) for you. Please contact with our sevice staff.

If you have any other questions,welcome to contact us.

| Application: | Industrial |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Single-Phase |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | Order Sample 1.1kw

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does an electric motor ensure efficient energy conversion?

An electric motor ensures efficient energy conversion by employing various design features and principles that minimize energy losses and maximize the conversion of electrical energy into mechanical energy. Here’s a detailed explanation of how electric motors achieve efficient energy conversion:

- Efficient Motor Design: Electric motors are designed with careful consideration given to their construction and materials. High-quality magnetic materials, such as laminated iron cores and permanent magnets, are used to reduce magnetic losses and maximize magnetic field strength. Additionally, the motor’s windings are designed with low-resistance conductors to minimize electrical losses. By optimizing the motor’s design, manufacturers can improve its overall efficiency.

- Reducing Friction and Mechanical Losses: Electric motors are designed to minimize friction and mechanical losses. This is achieved through the use of high-quality bearings and lubrication systems that reduce friction between moving parts. By reducing friction, the motor can operate more efficiently, translating more of the input energy into useful mechanical work rather than dissipating it as heat.

- Efficient Control and Power Electronics: Electric motors employ advanced control techniques and power electronics to enhance energy conversion efficiency. Variable frequency drives (VFDs) are commonly used to control motor speed and torque, allowing the motor to operate at optimal efficiency levels under varying load conditions. Power electronics devices, such as insulated gate bipolar transistors (IGBTs) and MOSFETs, minimize switching losses and optimize power flow within the motor.

- Regenerative Braking and Energy Recovery: Some electric motors, particularly those used in hybrid electric vehicles (HEVs) and electric trains, incorporate regenerative braking systems. These systems convert the kinetic energy of the moving vehicle back into electrical energy, which can be stored and reused. By capturing and reusing energy that would otherwise be wasted as heat during braking, regenerative braking significantly improves overall energy efficiency.

- Efficient Cooling and Thermal Management: Electric motors generate heat during operation, and excessive heat can lead to energy losses and reduced efficiency. To mitigate this, motors are designed with efficient cooling systems such as fans, heat sinks, or liquid cooling methods. Proper thermal management ensures that the motor operates within the optimal temperature range, reducing losses and improving overall efficiency.

- High-Efficiency Standards and Regulations: Governments and organizations have established energy efficiency standards and regulations for electric motors. These standards encourage manufacturers to produce motors with higher efficiency ratings. Compliance with these standards ensures that motors meet certain efficiency criteria, resulting in improved energy conversion and reduced energy consumption.

By incorporating these design features, control techniques, and efficiency measures, electric motors achieve efficient energy conversion. They minimize energy losses due to factors such as resistance, friction, and heat dissipation, ensuring that a significant portion of the input electrical energy is converted into useful mechanical work. The continuous advancements in motor design, materials, and control technologies further contribute to improving the overall energy efficiency of electric motors.

How do electric motors impact the overall productivity of manufacturing processes?

Electric motors have a significant impact on the overall productivity of manufacturing processes. Their versatility, reliability, and efficiency make them essential components in a wide range of industrial applications. Here’s a detailed explanation of how electric motors contribute to enhancing productivity in manufacturing:

- Mechanization and Automation: Electric motors serve as the primary power source for a vast array of industrial machinery and equipment. By providing mechanical power, electric motors enable mechanization and automation of manufacturing processes. They drive conveyor belts, pumps, compressors, robots, and other machinery, allowing for efficient material handling, assembly, and production operations. The use of electric motors in mechanized and automated systems reduces manual labor, accelerates production rates, and improves overall productivity.

- Precise Control and Repeatable Movements: Electric motors offer precise control over speed, position, and torque, enabling accurate and repeatable movements in manufacturing processes. This precision is crucial for tasks that require consistent and controlled operations, such as precision cutting, drilling, machining, and assembly. Electric motors allow for fine adjustments and control, ensuring that manufacturing operations are performed with high levels of accuracy and repeatability, which ultimately enhances productivity and product quality.

- High Speed and Acceleration: Electric motors are capable of achieving high rotational speeds and rapid acceleration, enabling fast-paced manufacturing processes. Motors with high-speed capabilities are utilized in applications that require quick operations, such as high-speed machining, packaging, and sorting. The ability of electric motors to rapidly accelerate and decelerate facilitates efficient cycle times and overall process throughput, contributing to increased productivity.

- Reliability and Durability: Electric motors are known for their reliability and durability, making them well-suited for demanding manufacturing environments. With proper maintenance, electric motors can operate continuously for extended periods, minimizing downtime due to motor failures. The reliability of electric motors ensures consistent and uninterrupted production, optimizing manufacturing productivity and reducing costly disruptions.

- Energy Efficiency: Electric motors have witnessed significant advancements in energy efficiency, leading to reduced energy consumption in manufacturing processes. Energy-efficient motors convert a higher percentage of electrical input power into useful mechanical output power, resulting in lower energy costs. By utilizing energy-efficient electric motors, manufacturers can achieve cost savings and improve the overall sustainability of their operations. Additionally, energy-efficient motors generate less heat, reducing the need for cooling and improving the overall efficiency of auxiliary systems.

- Integration with Control Systems: Electric motors can be seamlessly integrated with sophisticated control systems and automation technologies. This integration allows for centralized control, monitoring, and optimization of manufacturing processes. Control systems can regulate motor speed, torque, and performance based on real-time data, enabling adaptive and efficient operations. The integration of electric motors with control systems enhances the overall productivity by optimizing process parameters, minimizing errors, and facilitating seamless coordination between different stages of manufacturing.

Electric motors significantly impact the overall productivity of manufacturing processes by enabling mechanization, automation, precise control, high-speed operations, reliability, energy efficiency, and integration with advanced control systems. Their versatility and performance characteristics make them indispensable in a wide range of industries, including automotive, electronics, aerospace, food processing, and more. By harnessing the power of electric motors, manufacturers can streamline operations, improve product quality, increase throughput, and ultimately enhance productivity in their manufacturing processes.

What industries and applications commonly use electric motors?

Electric motors are widely utilized in various industries and applications due to their versatility, efficiency, and controllability. Here’s a detailed overview of the industries and applications where electric motors are commonly employed:

- Industrial Manufacturing: Electric motors are extensively used in industrial manufacturing processes. They power machinery and equipment such as conveyor systems, pumps, compressors, fans, mixers, robots, and assembly line equipment. Electric motors provide efficient and precise control over motion, making them essential for mass production and automation.

- Transportation: Electric motors play a crucial role in the transportation sector. They are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) to drive the wheels, providing propulsion. Electric motors offer benefits such as high torque at low speeds, regenerative braking, and improved energy efficiency. They are also employed in trains, trams, ships, and aircraft for various propulsion and auxiliary systems.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for air circulation, fans, blowers, and pumps. Electric motors help in maintaining comfortable indoor environments and ensure efficient cooling, heating, and ventilation in residential, commercial, and industrial buildings.

- Appliances and Household Devices: Electric motors are found in numerous household appliances and devices. They power refrigerators, washing machines, dryers, dishwashers, vacuum cleaners, blenders, food processors, air conditioners, ceiling fans, and many other appliances. Electric motors enable the necessary mechanical actions for these devices to function effectively.

- Renewable Energy: Electric motors are integral components of renewable energy systems. They are used in wind turbines to convert wind energy into electrical energy. Electric motors are also employed in solar tracking systems to orient solar panels towards the sun for optimal energy capture. Additionally, electric motors are utilized in hydroelectric power plants for controlling water flow and generating electricity.

- Medical Equipment: Electric motors are crucial in various medical devices and equipment. They power surgical tools, pumps for drug delivery and fluid management, diagnostic equipment, dental drills, patient lifts, wheelchair propulsion, and many other medical devices. Electric motors provide the necessary precision, control, and reliability required in healthcare settings.

- Robotics and Automation: Electric motors are extensively used in robotics and automation applications. They drive the joints and actuators of robots, enabling precise and controlled movement. Electric motors are also employed in automated systems for material handling, assembly, packaging, and quality control in industries such as automotive manufacturing, electronics, and logistics.

- Aerospace and Defense: Electric motors have significant applications in the aerospace and defense sectors. They are used in aircraft for propulsion, control surfaces, landing gear, and auxiliary systems. Electric motors are also employed in military equipment, drones, satellites, guided missiles, and underwater vehicles.

These are just a few examples of the industries and applications where electric motors are commonly used. Electric motors provide a reliable, efficient, and controllable means of converting electrical energy into mechanical energy, making them essential components in numerous technologies and systems across various sectors.

editor by CX 2023-12-15

China best GOST Standard Asynchronous AC Electric Motor for Blower Axial Fan Water Pump Air Compressor Gear Box with Best Sales

Item Description

GOST Normal Asynchronous AC Electric powered Motor for Blower Axial Fan Water Pump Air Compressor Gear Box

| Frame size | 56A- 355M |

| Pole | two-10 |

| Rated voltage | 380V |

| Frequency | 50Hz |

| Power | .18kw-315Kw |

| Protection degree | IP54 |

| Cooling method | IC411 |

| Insulation class | F |

| Ambient Temperature | -15°C~40°C |

| Altitude | not exceed 1000 Meter |

| Working Duty | S1(Constant) |

Item Description

Manufacturing facility and Production Line

Software fields

machine equipment, water pump, blower, compressor, and transportation, print, agriculture, food and much more industries.

Certifications

FAQ

Q: What is your MOQ of this product?

A: 5PCS.

For the first time cooperation, we acknowledge demo sample buy.

Q: What is your payment conditions?

A: 30% T/T deposit, 70% harmony just before cargo or L/C at sight.

Q: What is actually the delivery time?

A: twenty five-thirty times following obtaining your L/C or T/T deposit.

Q: Can we utilised our personal manufacturer on motors ?

A: Certain, we can supply OEM support,

manufacture with your authorized manufacturer.

Q: How lengthy is your guarantee?

A: 12 months right after getting B/L.

Staff

Motor Summary

An AC motor is a typical kind of electric motor that is pushed by alternating recent. As the most productive sensible motors for each day industrial programs (as effectively as hobbyist projects, home products, and all other skilled tools and buyer items), AC motors provide a comparatively successful method of making mechanical power from a basic electrical input signal.

DC motors use strength from batteries or other producing sources that provide a continuous voltage. A DC motor is composed of a number of components, the most well-known of which incorporate bearings, shafts, and gearboxes or gears. DC motors give better velocity variation and control and produce much more torque than AC motors. The two sorts of DC motors incorporate Brushed motors: Brushed motors are one of the oldest types and are internally commutated motors pushed by DC current. A brushed motor is made up of a rotor, brushes, and a shaft. The demand and polarity of the brushes control the path and velocity of the motor. Brushless Motors: In current a long time, brushless motors have become well-known for numerous purposes, largely due to the fact of their performance. Brushless motors are constructed in the same way as brushed motors, minus the brushes of system. Brushless motors also consist of focused circuitry to control speed and path. In brushless motors, magnets are mounted about the rotor, an efficiency-boosting configuration.

China OEM Ye3 0.75kw-4p Three-Phase AC Asynchronous Squirrel-Cage Induction Electric Motor for Water Pump, Air Compressor near me shop

Item Description

> Product Introduction

Gphq Y2/YE2 15HP/CV 11kw Cast Iron 3 Phase Electrical AC Motor

Y2/ YE2 Collection Solid Iron Three Section Induction Motor is specially created for European market place, whose terminal box is located on the leading of motor.They are totally enclosed and admirer-cooling designed. They are newly created in conformity with the relevant demands / rules of IEC requirements.

For the Connection Product of 2p 4p 6p 8p Y2 motor, please refer to the Identify Plate on the motor (The Y Connection is adopted by motors’ Output equivalent or under 3kW The Delta-Link is adopted by motors’ Output above 4kW).

| Power: | .55kw-315kw | Voltage: | 380/415/440V( can can carried out as your need) |

| Frequency: | 50/60hz | Enamelled Wire: | Copper Wire (Can Done Aluminum wire as Your Need) |

| Insulation Course: | F | Mounting Way: | B3 Foot /B5 Flange /B35 Foot and Flange |

| Security Grade: | IP55 | motor entire body : | solid iron physique of ac motor |

> Applications

Common location and machine with no special requirments, for example: equipment instruments, pumps, enthusiasts, transportation equipment, mixer, agriculture equipment, food equipment, agitator, air compressor and so forth. We also can supply aluminum housing variety for body dimensions below the regular of IEC.

> Our Electrical Motor Advantages

1. Wonderful top quality of supplies(Cold silicon steel/a hundred% copper wire/ Aluminum body)

two.Colourful wiring

three.Obvious nameplate

4.Reliable bundle

5.Higher efficiency, low sounds

six.Best materials make greatest efficiency

FAQ

1, Q:what is your MOQ for ac synchronous motor ?

A: 5pc is okay for each and every kind electrical motor

two, Q: What about your warranty for your 3 phase motor?

A: 1 yr ,but except male-produced wrecked

three, Q: which payment way you can settle for ?

A: TT, western union .

four, Q: how about your payment way ?

A: a hundred%payment in innovative considerably less $5000 ,30% payment in advanced payment , 70% payment just before sending in excess of $5000.

5, Q: how about your packing of induction motor ?

A: carton or plywood scenario ,if considerably less 1 container , we can pack all goods with pallet for little dimensions motor

six, Q: What details ought to be provided, if I buy electric powered ac motor from you ?

A: rated power, pace or pole ,variety ,voltage , mounting way , quantity , if far more is greater.

The rotor of a reluctance motor is made up of a strong cast steel part with a convex toothed rack. Their commencing process is similar to an induction motor, but it operates like a synchronous motor. Usually, their rotors have fewer poles than stators, which minimizes torque ripple and prevents ideal pole alignment, as no torque is made in that place. Reluctance motors variety in electrical power rankings from a couple of watts to about 22 kilowatts.

Synchronous motors operate at a pace that is synchronous with the frequency of the mains present. This means that in the constant-condition of the motor, the rotation of the shaft is synchronized with the frequency of the supply present. The interval of rotation of the shaft is equal to the number of AC cycles. The stator of a synchronous motor has polyphase AC electromagnets. These electromagnets make a magnetic field that rotates in synchrony with the recent in the wire. The rotor geared up with long term magnets or electromagnets rotates synchronously with the stator magnetic field to sort the 2nd synchronous rotating magnetic discipline of the AC motor.

China high quality Ye3 220kw-6p Three-Phase AC Asynchronous Squirrel-Cage Induction Electric Motor for Water Pump, Air Compressor near me factory

Merchandise Description

The YE3 series quality performance a few-phase asynchronous motor is inline with IE3 effectiveness standard in the provisions of IEC60034-30-2008.And the enhancement of the effectiveness in its layout is in line with the state’s demands on the energy preserving and use minimizing of the production sector.

YE3 collection high quality effectiveness a few-phase asynchronous motor with the mounting dimension in accordance with common IEC60034,it has good functions like the best possible construction, desirable visual appeal, lower sounds, high performance, substantial safety course as properly as substantial insulation class.YE3 sequence quality efficiency three-stage asynchronous motor can be broadly employed in various varieties of common use machineries like enthusiasts, pumps, equipment instruments, compressors, transportation and so on, and can also be utilized in the dangerous areas with oil and chemical, steel plants, mining business.

Detail:

Running circumstances

Ambient temperature: -20senti degree≤ 0≤ 40senti degree

Altitude:decrease than a thousand meters earlier mentioned sea stage

Temperature and Insulation class

Motors are dependent on F (155ºC) ,B (80K),

to keep motor existence and dependability

Cooling and Air flow

Entirely enclosed self fan cooling(TEFC).

Motor is mounted with auxiliary stream sort

Plastic fan which is complying with

the provisions of 60034-6 IEC Ic411

Insulation class

Motor security course is Ip55 which

can be used for dust or humidity

surroundings, and we can supply

a greater degree of security of motor

Motor defense

AS need, motor can be set up of PTC,

Pt100 and other winding resistance and

Bearing temperature measurement and

Security unit.

Voltage and frequency

The common voltage is 380V/50Hz.

which can be made between

200-600V,in the case of deviation

5%, the motor still can function excellent.

Vibration

Vibration pace of Ye3 collection motor

in the no-load is in line with course A,

specific requirement, we can supply

course B.

Terminals block box spot

The terminal block box is on the

top or 1 the correct aspect as the regular

Ye2 series motor.

Good quality assurance

From style to produce factory,

we strictly comply with the ISO9001 high quality

certification program and processes.

Polyphase motors can be possibly two-section or 3-section motors. They function like single-period induction motors, but both one-section and polyphase motors operate on a rotating magnetic discipline. Their rotating magnetic fields are produced by two- or 3-section currents passing by way of two or much more sets of coils. The rotating magnetic field produces torque. Polyphase motors are used in apps that demand large electrical power, these kinds of as the energy travel of compressors, hydraulic pumps, air conditioning compressors, and irrigation pumps.

AC motors are also diverse from DC motors because most AC motors do not incorporate brushes. This implies that upkeep and components substitute requirements for AC motors are inclined to be substantially lowered, with most customers typically anticipating a for a longer time common lifespan. As opposed to DC motors, the output pace of many varieties of AC motors is usually identified by inverter manage – once more, we will briefly outline a selection of likely variants on the simple AC motor product.

Auto shop made in China – replacement parts – in Portland United States AC Compressor for VW Touran for Audi A3 1K0820803L with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

About Product

| Product Name | Auto AC compressor for VW for Audi A3 |

| Part No. | 1K 0571 71S 1K0820803L |

| Specification | Voltage : 12 V Belt Pulley :120mm Number of Ribs : 6 |

| MOQ | 1 EPT if we have them in stock, 20pcs for production |

| Warranty | 12 months |

| Type | 100% brand new |

| Delivery time | 7-35 days |

Packing & Shipping

Each Air Conditioner Compressor will be packed in inner box with poly bag and foam. Two pieces will be packed in a carton. Several cartons will be packed on pallets.

FAQ

Q1. Can you produce according to sample or technical drawing?

A: We have very professional engineers who can well study samples and

drawings. So we surely can produce according to samples and technical drawings.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Ali Trade Assurance is also welcomed.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 15 to 60 days after receiving your advance payment. The specific delivery time depends on the items and

the quantity of your order.

Q5. How you ensure the quality?

A: We have whole set of te EPT machine and professional te EPT team. Every product is well tested before shipment.

Q6. How about the warranty?

A: Normally, warranty is 12 months after you receiving the goods. For some special products the warranty is longer.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.