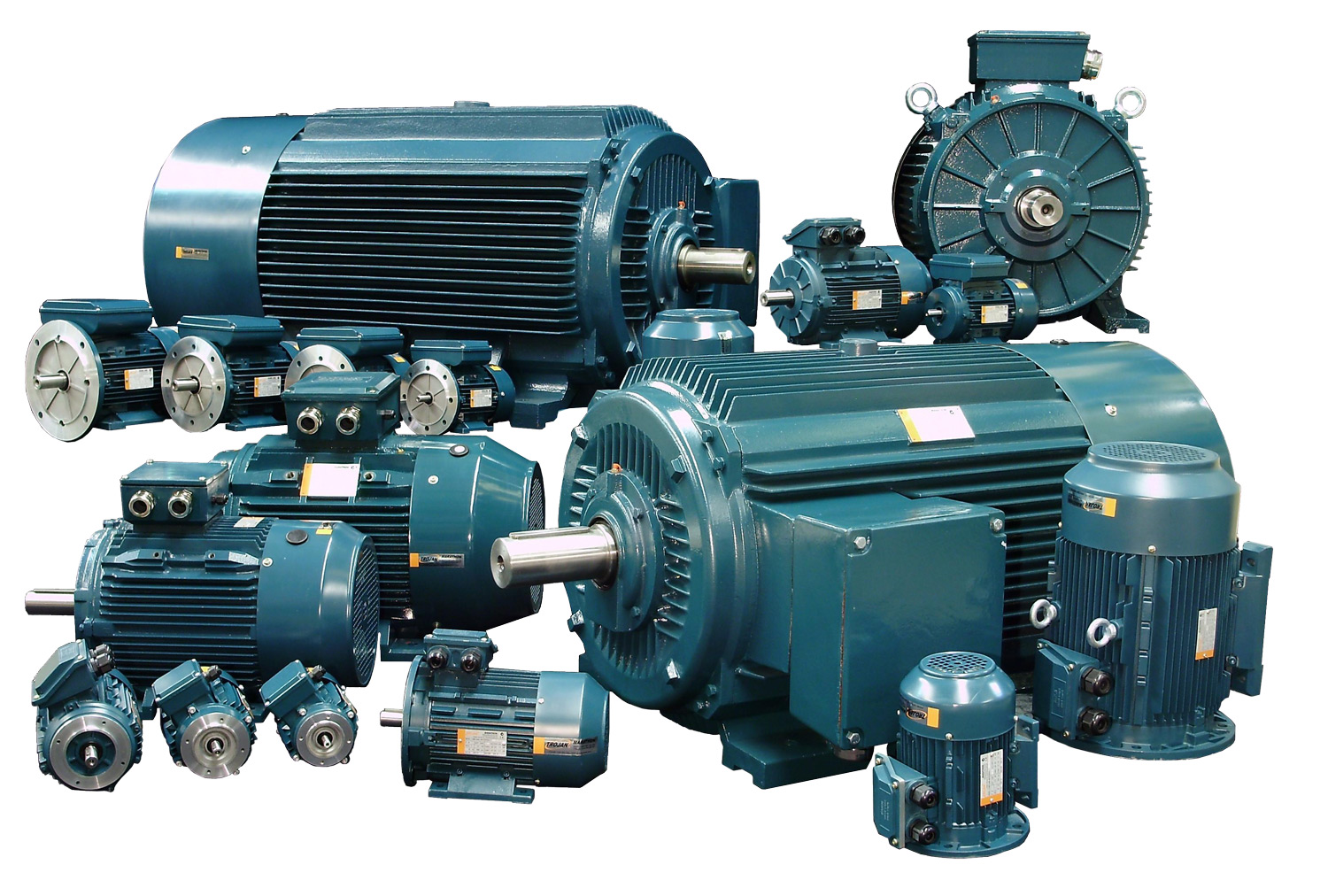

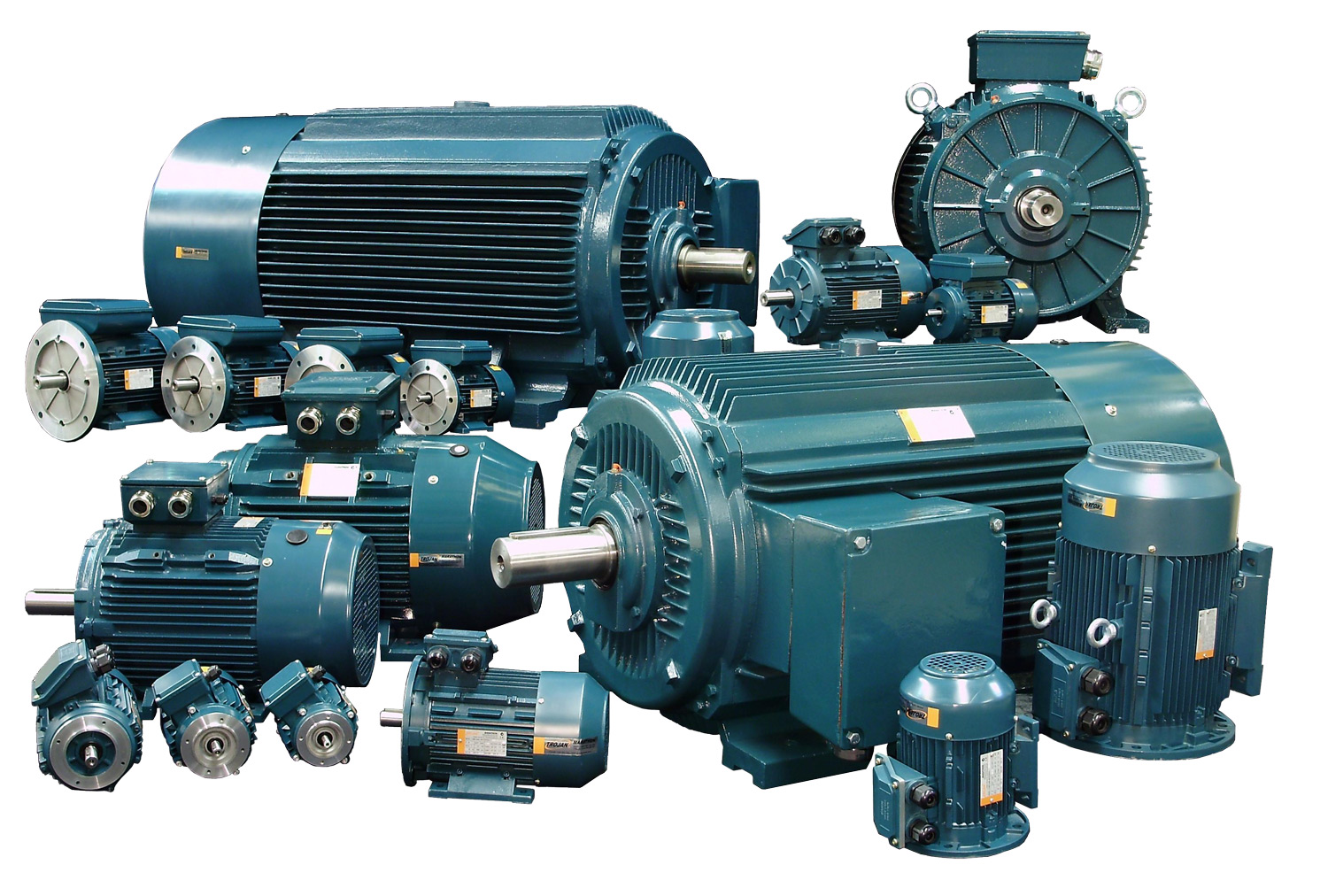

Product Description

Product Description

Features: High efficiency and energy saving, low noise and little vibration. Insulation class: F;Protection class:IP54 or IP55.

General purpose including cutting machines, pumps, fans, conveyors, machines tools of farm duty and food process.

The altitude not exceeding 1000m above sea level. The ambient temperature subject to seasonal variations but no exceeding+40ºC and not less than-15ºC.

Company Profile

ZheJiang Lanyoung Electromechanical Co., Ltd was originated from 1988, established in 2001, it owns ZheJiang Lanyoung Electromechanical Co., Ltd HangZhouShan City Branch and ZHangZhoug HangZhouang Electromechanical Co., Ltd, won the honorary title of “top 10 brands of brand network in 2019” and “excellent demonstration unit of ZHangZhoug focusing on quality and brand-making”. We are a modern company combining mechanical and electrical products research, development, production, sales and service with a long history and rich experience in production. We are experts of water pumps, motors, and fans products, the main products are stainless steel pumps, plastic corrosion-resistant submersible pumps, DC electric pumps, self-priming pump, machine tool cooling pumps, corrosion resistant pumps, sewage pumps, oil-immersed submersible pumps, blowers, medium pressure fan, multi-wing fan and so on, and we also possess practical new-type patent for a mini submersible pump. The above products can be all customized according to customer’s requirement. We have special advantages that is different from other manufacturing companies.

Product Parameters

| Type | Power | Pole/Speed | Volt/Frequency | Insulation | Protection | Motor housing | Mount |

| kw /HP | |||||||

| 80M2 | 0.55/0.75 | 6/885rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 90S | 0.75/1 | 6/910rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 90L | 1.1/1.5 | 6/910rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 100L | 1.5/2 | 6/940rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 112M | 2.2/3 | 6/940rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 132S | 3/4 | 6/960rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 132M1 | 4/5.5 | 6/960rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 132M2 | 5.5/7.5 | 6/960rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 160M | 7.5/10 | 6/970rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 160L | 11/15 | 6/970rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 180L | 15/20 | 6/970rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 200L1 | 18.5/25 | 6/980rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 200L2 | 22/30 | 6/980rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 225M | 30/40 | 6/980rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 250M | 37/50 | 6/980rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 280S | 45/60 | 6/985rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 280M | 55/75 | 6/985rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 315S | 75/100 | 6/990rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

Detailed Photos

Packaging & Shipping

Certifications

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Operating Speed: | Constant Speed |

| Number of Stator: | Three-Phase |

| Samples: |

US$ 29/Piece

1 Piece(Min.Order) | Order Sample Blue

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do manufacturers ensure the quality and reliability of electric motors?

Manufacturers employ several measures and quality control processes to ensure the quality and reliability of electric motors. These measures span from design and manufacturing stages to testing and inspections. Here’s a detailed explanation of how manufacturers ensure the quality and reliability of electric motors:

- Robust Design and Engineering: Manufacturers invest significant effort in designing electric motors with robust engineering principles. This involves careful selection of materials, precise calculations, and simulation techniques to ensure optimal performance and durability. Thorough design reviews and analysis are conducted to identify potential issues and optimize the motor’s design for reliability.

- Stringent Manufacturing Processes: Manufacturers adhere to stringent manufacturing processes to maintain consistent quality standards. This includes using advanced manufacturing technologies, automated assembly lines, and precision machining to ensure accurate and reliable motor production. Strict quality control measures are implemented at each stage of manufacturing, including material inspection, component testing, and assembly verification.

- Quality Control and Testing: Comprehensive quality control and testing procedures are implemented to assess the performance and reliability of electric motors. This includes electrical testing to verify motor characteristics such as voltage, current, power consumption, and efficiency. Mechanical testing is conducted to assess factors like torque, vibration, and noise levels. Additionally, endurance tests are performed to evaluate the motor’s performance over extended operating periods.

- Certifications and Compliance: Electric motor manufacturers often obtain certifications and comply with industry standards to ensure quality and reliability. These certifications, such as ISO 9001, IEC standards, and UL certifications, demonstrate that the manufacturer follows recognized quality management systems and meets specific requirements for product safety, performance, and reliability. Compliance with these standards provides assurance to customers regarding the motor’s quality.

- Reliability Testing: Manufacturers conduct extensive reliability testing to assess the motor’s performance under various conditions and stress factors. This may include accelerated life testing, temperature and humidity testing, thermal cycling, and load testing. Reliability testing helps identify potential weaknesses, evaluate the motor’s robustness, and ensure it can withstand real-world operating conditions without compromising performance or reliability.

- Continuous Improvement and Feedback: Manufacturers emphasize continuous improvement by gathering feedback from customers, field testing, and warranty analysis. By monitoring the performance of motors in real-world applications, manufacturers can identify any issues or failure patterns and make necessary design or process improvements. Customer feedback also plays a crucial role in driving improvements and addressing specific requirements.

- Quality Assurance and Documentation: Manufacturers maintain comprehensive documentation throughout the production process to ensure traceability and quality assurance. This includes recording and tracking raw materials, components, manufacturing parameters, inspections, and testing results. Proper documentation allows manufacturers to identify any deviations, track the motor’s history, and enable effective quality control and post-production analysis.

- Supplier Evaluation and Control: Manufacturers carefully evaluate and select reliable suppliers for motor components and materials. Supplier quality control processes are established to ensure that the sourced components meet the required specifications and quality standards. Regular supplier audits, inspections, and quality assessments are conducted to maintain a consistent supply chain and ensure the overall quality and reliability of the motors.

By implementing these measures, manufacturers ensure the quality and reliability of electric motors. Through robust design, stringent manufacturing processes, comprehensive testing, compliance with standards, continuous improvement, and effective quality control, manufacturers strive to deliver electric motors that meet or exceed customer expectations for performance, durability, and reliability.

What advancements in electric motor technology have improved energy efficiency?

Advancements in electric motor technology have played a crucial role in improving energy efficiency, leading to more sustainable and environmentally friendly applications. Here’s a detailed explanation of some key advancements in electric motor technology that have contributed to enhanced energy efficiency:

- High-Efficiency Motor Designs: One significant advancement in electric motor technology is the development of high-efficiency motor designs. These designs focus on reducing energy losses during motor operation, resulting in improved overall efficiency. High-efficiency motors are engineered with optimized stator and rotor geometries, reduced core losses, and improved magnetic materials. These design enhancements minimize energy wastage and increase the motor’s efficiency, allowing it to convert a higher percentage of electrical input power into useful mechanical output power.

- Premium Efficiency Standards: Another notable advancement is the establishment and adoption of premium efficiency standards for electric motors. These standards, such as the International Electrotechnical Commission (IEC) IE3 and NEMA Premium efficiency standards, set minimum efficiency requirements for motors. Manufacturers strive to meet or exceed these standards by incorporating innovative technologies and design features that enhance energy efficiency. The implementation of premium efficiency standards has led to the widespread availability of more efficient motors in the market, encouraging energy-conscious choices and reducing energy consumption in various applications.

- Variable Speed Drives: Electric motor systems often operate under varying load conditions, and traditional motor designs operate at a fixed speed. However, the development and adoption of variable speed drives (VSDs) have revolutionized motor efficiency. VSDs, such as frequency converters or inverters, allow the motor’s speed to be adjusted according to the load requirements. By operating motors at the optimal speed for each task, VSDs minimize energy losses and significantly improve energy efficiency. This technology is particularly beneficial in applications with variable loads, such as HVAC systems, pumps, and conveyors.

- Improved Motor Control and Control Algorithms: Advanced motor control techniques and algorithms have contributed to improved energy efficiency. These control systems employ sophisticated algorithms to optimize motor performance, including speed control, torque control, and power factor correction. By precisely adjusting motor parameters based on real-time operating conditions, these control systems minimize energy losses and maximize motor efficiency. Additionally, the integration of sensor technology and feedback loops enables closed-loop control, allowing motors to respond dynamically and adaptively to changes in load demand, further enhancing energy efficiency.

- Use of Permanent Magnet Motors: Permanent magnet (PM) motors have gained popularity due to their inherent high energy efficiency. PM motors utilize permanent magnets in the rotor, eliminating the need for rotor windings and reducing rotor losses. This design enables PM motors to achieve higher power densities, improved efficiency, and enhanced performance compared to traditional induction motors. The use of PM motors is particularly prevalent in applications where high efficiency and compact size are critical, such as electric vehicles, appliances, and industrial machinery.

- Integration of Advanced Materials: Advances in materials science have contributed to improved motor efficiency. The utilization of advanced magnetic materials, such as rare-earth magnets, allows for stronger and more efficient magnetic fields, resulting in higher motor efficiency. Additionally, the development of low-loss electrical steel laminations and improved insulation materials reduces core losses and minimizes energy wastage. These advanced materials enhance the overall efficiency of electric motors, making them more energy-efficient and environmentally friendly.

The advancements in electric motor technology, including high-efficiency motor designs, premium efficiency standards, variable speed drives, improved motor control, permanent magnet motors, and advanced materials, have collectively driven significant improvements in energy efficiency. These advancements have led to more efficient motor systems, reduced energy consumption, and increased sustainability across a wide range of applications, including industrial machinery, transportation, HVAC systems, appliances, and renewable energy systems.

How do electric motors handle variations in load, speed, and torque?

Electric motors are designed to handle variations in load, speed, and torque through various control mechanisms and techniques. Here’s a detailed explanation of how electric motors handle these variations:

- Load Variations: Electric motors can handle variations in load by adjusting the amount of torque they produce. When the load on the motor increases, such as when additional resistance or weight is applied, the motor responds by increasing the torque output. This is achieved through the control of the motor’s input current or voltage. For example, in DC motors, increasing the current supplied to the motor can compensate for the increased load, ensuring that the motor can continue to operate at the desired speed.

- Speed Variations: Electric motors can handle variations in speed by adjusting the frequency of the power supply or by varying the voltage applied to the motor. In AC motors, the speed is determined by the frequency of the alternating current, so changing the frequency can alter the motor’s speed. In DC motors, the speed can be controlled by adjusting the voltage applied to the motor. This can be achieved using electronic speed controllers (ESCs) or by employing pulse width modulation (PWM) techniques to control the average voltage supplied to the motor.

- Torque Variations: Electric motors can handle variations in torque by adjusting the current flowing through the motor windings. The torque produced by a motor is directly proportional to the current flowing through the motor. By increasing or decreasing the current, the motor can adjust its torque output to match the requirements of the load. This can be accomplished through various control methods, such as using motor drives or controllers that regulate the current supplied to the motor based on the desired torque.

- Control Systems: Electric motors often incorporate control systems to handle variations in load, speed, and torque more precisely. These control systems can include feedback mechanisms, such as encoders or sensors, which provide information about the motor’s actual speed or position. The feedback signals are compared to the desired speed or position, and the control system adjusts the motor’s input parameters accordingly to maintain the desired performance. This closed-loop control allows electric motors to respond dynamically to changes in load, speed, and torque.

In summary, electric motors handle variations in load, speed, and torque through various control mechanisms. By adjusting the current, voltage, or frequency of the power supply, electric motors can accommodate changes in load and speed requirements. Additionally, control systems with feedback mechanisms enable precise regulation of motor performance, allowing the motor to respond dynamically to variations in load, speed, and torque. These control techniques ensure that electric motors can operate effectively across a range of operating conditions and adapt to the changing demands of the application.

editor by CX 2024-05-16

China supplier YE4 IE4 0.55-315kw Super Premium Efficiency Three Phase Induction Electric AC Asynchronous Induction Motor vacuum pump oil

Product Description

YE4 series high efficiency 3 phase induction motors have advantage for high efficiency, good starting performance, low noice, improved structure, improved cooling capabilities, is widely used for general motors and can be used to drive all kinds of general purpose machines such as compressors, ventilators, pumps, ect. Other uses such as petrol chimical, medical, chemical industries and mining.

Speed 3000RPM 2-Pole 50Hz

Speed 1500RPM 4-Pole 50Hz

Speed 1000RPM 6-Pole 50Hz

Speed 750RPM 8-Pole 50Hz

FAQ

1.What’re your main products ?

We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

2. How to select a suitable motor?

If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

3.Do you have a customized service for your standard motors?

Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

4. Do you have an individual design service for motors?

Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

5. Can I have samples for testing first?

Yes, definitely you can. After confirmed the needed motor specs, we will quote and provide a proforma invoice for samples, once we get the payment, we will get a PASS from our account department to proceed samples accordingly.

6.How do you make sure motor quality?

We have our own inspection procedures: for incoming materials, we have signed sample and drawing to make sure qualified incoming materials; for production process, we have tour inspection in the process and final inspection to make sure qualified products before shipping.

7.What’s your lead time?

Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Weclome contact with us if have any questions about this motor or other products!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Operating Speed: | Low Speed |

| Number of Stator: | Three-Phase |

| Species: | Y, Y2 Series Three-Phase |

| Rotor Structure: | Squirrel-Cage |

| Casing Protection: | Protection Type |

| Samples: |

US$ 480/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of machinery or equipment that rely on electric motors?

Electric motors are extensively used in various machinery and equipment across different industries. They play a crucial role in converting electrical energy into mechanical energy to power a wide range of applications. Here are some examples of machinery and equipment that heavily rely on electric motors:

- Industrial Machinery: Electric motors are found in numerous industrial machinery and equipment, such as pumps, compressors, fans, conveyors, agitators, mixers, and machine tools. These motors provide the necessary power for moving fluids, gases, and materials, as well as driving mechanical processes in manufacturing, mining, construction, and other industrial applications.

- Electric Vehicles: Electric motors are the primary propulsion system in electric vehicles (EVs) and hybrid electric vehicles (HEVs). They provide the power needed to drive the wheels and propel the vehicle. Electric motors in EVs and HEVs offer high efficiency, instant torque, and regenerative braking capabilities, contributing to the advancement of sustainable transportation.

- Household Appliances: Many household appliances rely on electric motors for their operation. Examples include refrigerators, air conditioners, washing machines, dishwashers, vacuum cleaners, blenders, and electric fans. Electric motors enable the movement, cooling, or mechanical functions in these appliances, enhancing convenience and efficiency in daily household tasks.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for various functions. Motors power the fans in air handling units, circulate air through ducts, and drive compressors in air conditioning and refrigeration systems. Electric motors in HVAC systems contribute to efficient temperature control and air circulation in residential, commercial, and industrial buildings.

- Medical Equipment: Electric motors are essential components in a wide array of medical equipment. Examples include MRI machines, X-ray machines, CT scanners, surgical robots, dental drills, infusion pumps, and patient lifts. These motors enable precise movements, imaging capabilities, and mechanical functions in medical devices, supporting diagnostics, treatment, and patient care.

- Power Tools: Electric motors are commonly used in power tools such as drills, saws, grinders, sanders, and routers. They provide the rotational force and power required for cutting, shaping, drilling, and other tasks. Electric motors in power tools offer portability, ease of use, and consistent performance for both professional and DIY applications.

- Aircraft Systems: Electric motors are increasingly utilized in aircraft systems. They power various components, including landing gear actuation systems, fuel pumps, hydraulic systems, and cabin air circulation systems. Electric motors in aircraft contribute to weight reduction, energy efficiency, and improved reliability compared to traditional hydraulic or pneumatic systems.

These examples represent just a fraction of the machinery and equipment that rely on electric motors. From industrial applications to household appliances and transportation systems, electric motors are integral to modern technology, providing efficient and reliable mechanical power for a wide range of purposes.

What safety precautions should be followed when working with electric motors?

Working with electric motors requires adherence to specific safety precautions to ensure the well-being of individuals and prevent accidents. Electric motors involve electrical hazards that can cause electric shock, burns, or other injuries if proper safety measures are not followed. Here’s a detailed explanation of the safety precautions that should be followed when working with electric motors:

- Qualified Personnel: It is important to assign work on electric motors to qualified personnel who have the necessary knowledge, training, and experience in electrical systems and motor operation. Qualified electricians or technicians should handle installation, maintenance, and repairs involving electric motors.

- De-Energization and Lockout/Tagout: Before performing any work on electric motors, they should be de-energized, and appropriate lockout/tagout procedures should be followed. This involves isolating the motor from the power source, ensuring that it cannot be energized accidentally. Lockout/tagout procedures help prevent unexpected startup and protect workers from electrical hazards.

- Personal Protective Equipment (PPE): When working with electric motors, appropriate personal protective equipment should be worn. This may include insulated gloves, safety glasses, protective clothing, and footwear with electrical insulation. PPE helps protect against potential electrical shocks, burns, and other physical hazards.

- Inspection and Maintenance: Regular inspection and maintenance of electric motors are essential to identify potential issues or defects that could compromise safety. This includes checking for loose connections, damaged insulation, worn-out components, or overheating. Any defects or abnormalities should be addressed promptly by qualified personnel.

- Proper Grounding: Electric motors should be properly grounded to prevent electrical shock hazards. Grounding ensures that any fault currents are redirected safely to the ground, reducing the risk of electric shock to individuals working on or around the motor.

- Avoiding Wet Conditions: Electric motors should not be operated or worked on in wet or damp conditions unless they are specifically designed for such environments. Water or moisture increases the risk of electrical shock. If working in wet conditions is necessary, appropriate safety measures and equipment, such as waterproof PPE, should be used.

- Safe Electrical Connections: When connecting or disconnecting electric motors, proper electrical connections should be made. This includes ensuring that power is completely switched off, using appropriate tools and techniques for making connections, and tightening electrical terminals securely. Loose or faulty connections can lead to electrical hazards, overheating, or equipment failure.

- Awareness of Capacitors: Some electric motors contain capacitors that store electrical energy even when the motor is de-energized. These capacitors can discharge unexpectedly and cause electric shock. Therefore, it is important to discharge capacitors safely before working on the motor and to be cautious of potential residual energy even after de-energization.

- Training and Knowledge: Individuals working with electric motors should receive proper training and have a good understanding of electrical safety practices and procedures. They should be knowledgeable about the potential hazards associated with electric motors and know how to respond to emergencies, such as electrical shocks or fires.

- Adherence to Regulations and Standards: Safety precautions should align with relevant regulations, codes, and standards specific to electrical work and motor operation. These may include local electrical codes, occupational safety guidelines, and industry-specific standards. Compliance with these regulations helps ensure a safe working environment.

It is crucial to prioritize safety when working with electric motors. Following these safety precautions, along with any additional guidelines provided by equipment manufacturers or local regulations, helps minimize the risk of electrical accidents, injuries, and property damage. Regular training, awareness, and a safety-focused mindset contribute to a safer working environment when dealing with electric motors.

Can you explain the basic principles of electric motor operation?

An electric motor operates based on several fundamental principles of electromagnetism and electromagnetic induction. These principles govern the conversion of electrical energy into mechanical energy, enabling the motor to generate rotational motion. Here’s a detailed explanation of the basic principles of electric motor operation:

- Magnetic Fields: Electric motors utilize magnetic fields to create the forces necessary for rotation. The motor consists of two main components: the stator and the rotor. The stator contains coils of wire wound around a core and is responsible for generating a magnetic field. The rotor, which is connected to the motor’s output shaft, has magnets or electromagnets that produce their own magnetic fields.

- Magnetic Field Interaction: When an electric current flows through the coils in the stator, it generates a magnetic field. This magnetic field interacts with the magnetic field produced by the rotor. The interaction between these two magnetic fields results in a rotational force, known as torque, that causes the rotor to rotate.

- Electromagnetic Induction: Electric motors can also operate on the principle of electromagnetic induction. In these motors, alternating current (AC) is supplied to the stator coils. The alternating current produces a changing magnetic field that induces a voltage in the rotor. This induced voltage then generates a current in the rotor, which creates its own magnetic field. The interaction between the stator’s magnetic field and the rotor’s magnetic field leads to rotation.

- Commutation: In certain types of electric motors, such as brushed DC motors, commutation is employed. Commutation refers to the process of reversing the direction of the current in the rotor’s electromagnets to maintain continuous rotation. This is achieved using a component called a commutator, which periodically switches the direction of the current as the rotor rotates. By reversing the current at the right time, the commutator ensures that the magnetic fields of the stator and the rotor remain properly aligned, resulting in continuous rotation.

- Output Shaft: The rotational motion generated by the interaction of magnetic fields is transferred to the motor’s output shaft. The output shaft is connected to the load or the device that needs to be driven, such as a fan, a pump, or a conveyor belt. As the motor rotates, the mechanical energy produced is transmitted through the output shaft, enabling the motor to perform useful work.

In summary, the basic principles of electric motor operation involve the generation and interaction of magnetic fields. By supplying an electric current to the stator and utilizing magnets or electromagnets in the rotor, electric motors create magnetic fields that interact to produce rotational motion. Additionally, the principle of electromagnetic induction allows for the conversion of alternating current into mechanical motion. Commutation, in certain motor types, ensures continuous rotation by reversing the current in the rotor’s electromagnets. The resulting rotational motion is then transferred to the motor’s output shaft to perform mechanical work.

editor by CX 2024-05-10

China Best Sales High Quality Three Phase AC Electric Induction Motor Electric Motor for Combi Oven with Best Sales

Product Description

FAQ

Q1.What service you can provide?

1) Focus on air centrifugal fan industry for 15 years, can provide advanced techniques support.

2) Professional service team with 24 hours service can make you without worries behind.

3) Enough stock can meet your instant demand.

4) Up to 12 months quality guarantee of products, you can rest assured to use.

5) Products have got 3C and CE certificates.

Q2. How do you ensure your products quality?

We are a professional and unique manufacturer of air blowers in Guandong province, China.

We have full set of production equipment in centrifugal fan industry and complete QC inspection system.

Q3. In order to recommend the suitable product to you, please help confirm the following information:

1) The application of the centrifugal fan

2) The technical parameter requirement

3) Order quantity

4) Special product requirements, such as changing the direction of outlet, special voltage requirements, etc.

Q4: What’s your payment terms ?

By T/T,LC ,40% deposit in advance, balance 60% before shipment.

Q5: How can I place the order?

First CHINAMFG the PI,pay deposit,then we will arrange the production.After finished production need you pay balance. Finally we will ship the Goods.

Q6: When can I get the quotation ?

We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or tell us in your mail, so that we could regard your inquiry priority.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | for Oven |

|---|---|

| Speed: | Low Speed |

| Number of Stator: | Single-Phase |

| Function: | for Heat Dissipation Cooling |

| Casing Protection: | Closed Type |

| Number of Poles: | 2 |

| Samples: |

US$ 33/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of machinery or equipment that rely on electric motors?

Electric motors are extensively used in various machinery and equipment across different industries. They play a crucial role in converting electrical energy into mechanical energy to power a wide range of applications. Here are some examples of machinery and equipment that heavily rely on electric motors:

- Industrial Machinery: Electric motors are found in numerous industrial machinery and equipment, such as pumps, compressors, fans, conveyors, agitators, mixers, and machine tools. These motors provide the necessary power for moving fluids, gases, and materials, as well as driving mechanical processes in manufacturing, mining, construction, and other industrial applications.

- Electric Vehicles: Electric motors are the primary propulsion system in electric vehicles (EVs) and hybrid electric vehicles (HEVs). They provide the power needed to drive the wheels and propel the vehicle. Electric motors in EVs and HEVs offer high efficiency, instant torque, and regenerative braking capabilities, contributing to the advancement of sustainable transportation.

- Household Appliances: Many household appliances rely on electric motors for their operation. Examples include refrigerators, air conditioners, washing machines, dishwashers, vacuum cleaners, blenders, and electric fans. Electric motors enable the movement, cooling, or mechanical functions in these appliances, enhancing convenience and efficiency in daily household tasks.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for various functions. Motors power the fans in air handling units, circulate air through ducts, and drive compressors in air conditioning and refrigeration systems. Electric motors in HVAC systems contribute to efficient temperature control and air circulation in residential, commercial, and industrial buildings.

- Medical Equipment: Electric motors are essential components in a wide array of medical equipment. Examples include MRI machines, X-ray machines, CT scanners, surgical robots, dental drills, infusion pumps, and patient lifts. These motors enable precise movements, imaging capabilities, and mechanical functions in medical devices, supporting diagnostics, treatment, and patient care.

- Power Tools: Electric motors are commonly used in power tools such as drills, saws, grinders, sanders, and routers. They provide the rotational force and power required for cutting, shaping, drilling, and other tasks. Electric motors in power tools offer portability, ease of use, and consistent performance for both professional and DIY applications.

- Aircraft Systems: Electric motors are increasingly utilized in aircraft systems. They power various components, including landing gear actuation systems, fuel pumps, hydraulic systems, and cabin air circulation systems. Electric motors in aircraft contribute to weight reduction, energy efficiency, and improved reliability compared to traditional hydraulic or pneumatic systems.

These examples represent just a fraction of the machinery and equipment that rely on electric motors. From industrial applications to household appliances and transportation systems, electric motors are integral to modern technology, providing efficient and reliable mechanical power for a wide range of purposes.

What safety precautions should be followed when working with electric motors?

Working with electric motors requires adherence to specific safety precautions to ensure the well-being of individuals and prevent accidents. Electric motors involve electrical hazards that can cause electric shock, burns, or other injuries if proper safety measures are not followed. Here’s a detailed explanation of the safety precautions that should be followed when working with electric motors:

- Qualified Personnel: It is important to assign work on electric motors to qualified personnel who have the necessary knowledge, training, and experience in electrical systems and motor operation. Qualified electricians or technicians should handle installation, maintenance, and repairs involving electric motors.

- De-Energization and Lockout/Tagout: Before performing any work on electric motors, they should be de-energized, and appropriate lockout/tagout procedures should be followed. This involves isolating the motor from the power source, ensuring that it cannot be energized accidentally. Lockout/tagout procedures help prevent unexpected startup and protect workers from electrical hazards.

- Personal Protective Equipment (PPE): When working with electric motors, appropriate personal protective equipment should be worn. This may include insulated gloves, safety glasses, protective clothing, and footwear with electrical insulation. PPE helps protect against potential electrical shocks, burns, and other physical hazards.

- Inspection and Maintenance: Regular inspection and maintenance of electric motors are essential to identify potential issues or defects that could compromise safety. This includes checking for loose connections, damaged insulation, worn-out components, or overheating. Any defects or abnormalities should be addressed promptly by qualified personnel.

- Proper Grounding: Electric motors should be properly grounded to prevent electrical shock hazards. Grounding ensures that any fault currents are redirected safely to the ground, reducing the risk of electric shock to individuals working on or around the motor.

- Avoiding Wet Conditions: Electric motors should not be operated or worked on in wet or damp conditions unless they are specifically designed for such environments. Water or moisture increases the risk of electrical shock. If working in wet conditions is necessary, appropriate safety measures and equipment, such as waterproof PPE, should be used.

- Safe Electrical Connections: When connecting or disconnecting electric motors, proper electrical connections should be made. This includes ensuring that power is completely switched off, using appropriate tools and techniques for making connections, and tightening electrical terminals securely. Loose or faulty connections can lead to electrical hazards, overheating, or equipment failure.

- Awareness of Capacitors: Some electric motors contain capacitors that store electrical energy even when the motor is de-energized. These capacitors can discharge unexpectedly and cause electric shock. Therefore, it is important to discharge capacitors safely before working on the motor and to be cautious of potential residual energy even after de-energization.

- Training and Knowledge: Individuals working with electric motors should receive proper training and have a good understanding of electrical safety practices and procedures. They should be knowledgeable about the potential hazards associated with electric motors and know how to respond to emergencies, such as electrical shocks or fires.

- Adherence to Regulations and Standards: Safety precautions should align with relevant regulations, codes, and standards specific to electrical work and motor operation. These may include local electrical codes, occupational safety guidelines, and industry-specific standards. Compliance with these regulations helps ensure a safe working environment.

It is crucial to prioritize safety when working with electric motors. Following these safety precautions, along with any additional guidelines provided by equipment manufacturers or local regulations, helps minimize the risk of electrical accidents, injuries, and property damage. Regular training, awareness, and a safety-focused mindset contribute to a safer working environment when dealing with electric motors.

How do electric motors handle variations in load, speed, and torque?

Electric motors are designed to handle variations in load, speed, and torque through various control mechanisms and techniques. Here’s a detailed explanation of how electric motors handle these variations:

- Load Variations: Electric motors can handle variations in load by adjusting the amount of torque they produce. When the load on the motor increases, such as when additional resistance or weight is applied, the motor responds by increasing the torque output. This is achieved through the control of the motor’s input current or voltage. For example, in DC motors, increasing the current supplied to the motor can compensate for the increased load, ensuring that the motor can continue to operate at the desired speed.

- Speed Variations: Electric motors can handle variations in speed by adjusting the frequency of the power supply or by varying the voltage applied to the motor. In AC motors, the speed is determined by the frequency of the alternating current, so changing the frequency can alter the motor’s speed. In DC motors, the speed can be controlled by adjusting the voltage applied to the motor. This can be achieved using electronic speed controllers (ESCs) or by employing pulse width modulation (PWM) techniques to control the average voltage supplied to the motor.

- Torque Variations: Electric motors can handle variations in torque by adjusting the current flowing through the motor windings. The torque produced by a motor is directly proportional to the current flowing through the motor. By increasing or decreasing the current, the motor can adjust its torque output to match the requirements of the load. This can be accomplished through various control methods, such as using motor drives or controllers that regulate the current supplied to the motor based on the desired torque.

- Control Systems: Electric motors often incorporate control systems to handle variations in load, speed, and torque more precisely. These control systems can include feedback mechanisms, such as encoders or sensors, which provide information about the motor’s actual speed or position. The feedback signals are compared to the desired speed or position, and the control system adjusts the motor’s input parameters accordingly to maintain the desired performance. This closed-loop control allows electric motors to respond dynamically to changes in load, speed, and torque.

In summary, electric motors handle variations in load, speed, and torque through various control mechanisms. By adjusting the current, voltage, or frequency of the power supply, electric motors can accommodate changes in load and speed requirements. Additionally, control systems with feedback mechanisms enable precise regulation of motor performance, allowing the motor to respond dynamically to variations in load, speed, and torque. These control techniques ensure that electric motors can operate effectively across a range of operating conditions and adapt to the changing demands of the application.

editor by CX 2024-05-08

China Hot selling Three Phase Explosion Proof Flameproof AC Electrical Asynchronous Induction Ex Electric Motor vacuum pump ac

Product Description

Product Description

Explosion-proof motor is 1 of the important electrical products in the petroleum, chemical and coal industries. Our explosion proof motor has high operational safety, excellent performance, low noise and vibration and meets the need of environment protection.

For the explosion proof high efficiency electric motor, we have YBX3, YBX4, YBX5 series, from 0.18KW to 315KW. For different voltage, frequency and different power, we can do the customized

Product Parameters

Application

The Conditions of Using of Electric/Electrical Induction Three Phase Ex-proof AC Motor :

| 1. The altitude does not exceed 1000 meters. Higher altitudes support customization. |

| 2. The highest ambient air temperature, no more than 40 ° C. Higher temperature support customization. |

| 3. The power frequency of ex-proof AC motor is 50Hz(60Hz) ± 1%. |

| 4.The variation range of working voltage shall not be greater than ± 5% of rated voltage. |

| 5.The ex-proof electric AC motor rating is continuous duty S1. |

| 6.Explosion-proof grade ExdIIBT4Gb, suitable for electric drive in underground coal mine (non-mining working face)and factories containing explosive gas mixture in line with the above standard in the workplace. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Operating Speed: | Constant Speed |

| Number of Stator: | Three-Phase |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What factors should be considered when selecting the right electric motor for a task?

When selecting the right electric motor for a task, several factors need to be considered to ensure optimal performance and compatibility. Here’s a detailed overview of the factors that should be taken into account:

- Load Requirements: The first consideration is understanding the specific load requirements of the task. This includes factors such as the torque or force needed to drive the load, the speed range required, and any variations in load that may occur. By accurately assessing the load requirements, you can determine the appropriate motor type, size, and characteristics needed to handle the task effectively.

- Motor Type: Different motor types are suited for specific applications. Common motor types include AC induction motors, brushless DC motors, brushed DC motors, and stepper motors. Each type has its own advantages and limitations in terms of speed range, torque characteristics, efficiency, control requirements, and cost. Choosing the right motor type depends on the task’s specific requirements and the desired performance.

- Power Supply: Consider the available power supply for the motor. Determine whether the application requires AC or DC power and the voltage and frequency range of the power source. Ensure that the motor’s power requirements align with the available power supply to avoid compatibility issues.

- Efficiency and Energy Consumption: Efficiency is an important factor to consider, especially for applications where energy consumption is a concern. Higher motor efficiency translates to lower energy losses and reduced operating costs over the motor’s lifetime. Look for motors with high efficiency ratings to minimize energy consumption and improve overall system efficiency.

- Environmental Factors: Assess the environmental conditions in which the motor will operate. Consider factors such as temperature, humidity, dust, and vibration. Some motors are specifically designed to withstand harsh environmental conditions, while others may require additional protection or enclosures. Choosing a motor that is suitable for the intended environment will ensure reliable and long-lasting operation.

- Control and Feedback Requirements: Determine whether the application requires precise control over motor speed, position, or torque. Some tasks may benefit from closed-loop control systems that incorporate feedback devices like encoders or sensors to provide accurate motor control. Evaluate the control and feedback requirements of the task and select a motor that is compatible with the desired control mechanism.

- Physical Constraints: Consider any physical constraints or limitations that may impact motor selection. These constraints may include space restrictions, weight limitations, mounting options, and mechanical compatibility with other components or equipment. Ensure that the chosen motor can physically fit and integrate into the system without compromising performance or functionality.

- Cost and Budget: Finally, consider the budget and cost constraints associated with the motor selection. Evaluate the initial purchase cost of the motor as well as the long-term operating costs, including maintenance and energy consumption. Strive to strike a balance between performance and cost-effectiveness to ensure the best value for your specific application.

By considering these factors, you can make an informed decision when selecting the right electric motor for a task. It is crucial to thoroughly analyze the requirements and match them with the motor’s specifications to achieve optimal performance, reliability, and efficiency.

How do electric motors contribute to the precision of tasks like robotics?

Electric motors play a critical role in enabling the precision of tasks in robotics. Their unique characteristics and capabilities make them well-suited for precise and controlled movements required in robotic applications. Here’s a detailed explanation of how electric motors contribute to the precision of tasks in robotics:

- Precise Positioning: Electric motors offer precise positioning capabilities, allowing robots to move with accuracy and repeatability. By controlling the motor’s speed, direction, and rotation, robots can achieve precise position control, enabling them to perform tasks with high levels of accuracy. This is particularly important in applications that require precise manipulation, such as assembly tasks, pick-and-place operations, and surgical procedures.

- Speed Control: Electric motors provide precise speed control, allowing robots to perform tasks at varying speeds depending on the requirements. By adjusting the motor’s speed, robots can achieve smooth and controlled movements, which is crucial for tasks that involve delicate handling or interactions with objects or humans. The ability to control motor speed precisely enhances the overall precision and safety of robotic operations.

- Torque Control: Electric motors offer precise torque control, which is essential for tasks that require forceful or delicate interactions. Torque control allows robots to exert the appropriate amount of force or torque, enabling them to handle objects, perform assembly tasks, or execute movements with the required precision. By modulating the motor’s torque output, robots can delicately manipulate objects without causing damage or apply sufficient force for tasks that demand strength.

- Feedback Control Systems: Electric motors in robotics are often integrated with feedback control systems to enhance precision. These systems utilize sensors, such as encoders or resolvers, to provide real-time feedback on the motor’s position, speed, and torque. The feedback information is used to continuously adjust and fine-tune the motor’s performance, compensating for any errors or deviations and ensuring precise movements. The closed-loop nature of feedback control systems allows robots to maintain accuracy and adapt to dynamic environments or changing task requirements.

- Dynamic Response: Electric motors exhibit excellent dynamic response characteristics, enabling quick and precise adjustments to changes in command signals. This responsiveness is particularly advantageous in robotics, where rapid and accurate movements are often required. Electric motors can swiftly accelerate, decelerate, and change direction, allowing robots to perform intricate tasks with precision and efficiency.

- Compact and Lightweight: Electric motors are available in compact and lightweight designs, making them suitable for integration into various robotic systems. Their small size and high power-to-weight ratio allow for efficient utilization of space and minimal impact on the overall weight and size of the robot. This compactness and lightness contribute to the overall precision and maneuverability of robotic platforms.

Electric motors, with their precise positioning, speed control, torque control, feedback control systems, dynamic response, and compactness, significantly contribute to the precision of tasks in robotics. These motors enable robots to execute precise movements, manipulate objects with accuracy, and perform tasks that require high levels of precision. The integration of electric motors with advanced control algorithms and sensory feedback systems empowers robots to adapt to various environments, interact safely with humans, and achieve precise and controlled outcomes in a wide range of robotic applications.

What are the different types of electric motors available?

There are various types of electric motors available, each designed for specific applications and operating principles. These motors differ in their construction, power sources, and performance characteristics. Here is an overview of some common types of electric motors:

- DC Motors: DC (Direct Current) motors are widely used and come in different configurations. The most common types include brushed DC motors and brushless DC motors. Brushed DC motors use brushes and a commutator to switch the direction of current in the rotor, while brushless DC motors use electronic commutation. DC motors offer good speed control and torque characteristics, making them suitable for applications like robotics, electric vehicles, and small appliances.

- AC Motors: AC (Alternating Current) motors are classified into several types, including induction motors, synchronous motors, and universal motors. Induction motors are popular for their simplicity and reliability. They operate based on electromagnetic induction and are commonly used in industrial and residential applications. Synchronous motors operate at a constant speed and are often used in applications that require precise control, such as industrial machinery and synchronous clocks. Universal motors are designed to operate on both AC and DC power sources and are commonly found in household appliances like vacuum cleaners and power tools.

- Stepper Motors: Stepper motors are designed to move in discrete steps or increments, making them suitable for applications that require precise positioning. They are often used in robotics, 3D printers, CNC machines, and other automated systems. Stepper motors are available in various configurations, including permanent magnet stepper motors, variable reluctance stepper motors, and hybrid stepper motors.

- Servo Motors: Servo motors are a type of motor that combines a DC motor with a feedback control mechanism. They are known for their precise control over position, velocity, and acceleration. Servo motors are commonly used in robotics, industrial automation, and applications that require accurate motion control, such as robotic arms, RC vehicles, and camera gimbals.

- Linear Motors: Linear motors are designed to produce linear motion instead of rotational motion. They operate on similar principles as rotary motors but with a different mechanical arrangement. Linear motors find applications in high-speed transportation systems, cutting machines, and other systems that require linear motion without the need for mechanical conversion from rotary to linear motion.

- Haptic Motors: Haptic motors, also known as vibration motors, are small motors used to create tactile feedback or vibrations in electronic devices. They are commonly found in smartphones, game controllers, wearable devices, and other gadgets that require haptic feedback to enhance the user experience.

These are just a few examples of the different types of electric motors available. Each type has its own advantages, limitations, and specific applications. The selection of an electric motor depends on factors such as the required torque, speed, control, efficiency, and the specific needs of the application at hand.

editor by CX 2024-05-03

China wholesaler Factory Direct Sale High Quality Three-Phase Single-Phase Explosion-Proof Industrial Engine AC Induction Asynchronous Electric Motor vacuum pump brakes

Product Description

Product Description

IE4 Series Three phase AC Motor

lE4 series ultra-high eficiency three-phase asynchronous motor is a highly eficient new upgraded product independently developed byour company. lts efficlency meets the level 2 energy efficiency standard of GB 186~8-2571 and IEC60034-30-1 lE4 efficiency index, The mounting dimensions confomms to lEC standard and national standard, customers can realize fast switching, YE4 series motor has the characteristisof beautiful appearance, low loss, low noise, low vibration, safe and reliable, easy maintenance, etc.The products are mainly equipped with fans, water pumps, compressors, engineering machinery and other equipment, which are widely used in ventilation and refrigeration, building, oil and gas, petrochemicals, coal gasification, metallurgy, electric power, nuclear power, ship building industrial automation and other fields.

Detailed Photos

Product Parameters

Certifications

Packaging & Shipping

Company Profile

Weiye motor Co.,Ltd. is located in Qiaowu Industrial zone, HangZhou City, ZHangZhoug Province, China, The company occupies 60,000 square CHINAMFG and owns advanced producing equipment,it is a company specialized in producing of all kinds of electric motors,The company was founded in 1999, Now it has been listed in the key industrial backbone enterprises in HangZhou City and one of the 5 strong enterprises in Zeguo Town.The company has a group of high-tech knowledge level of technical personnel and staff team, With advanced development mode and perfect modern management system , all products are according to the international IEC standard, it has passed ISO9001:2008 international quality system certification, and got CCC,CECP,CE certificate. CHINAMFG is 1 of the biggest motor export enterprises in electrical area.

CHINAMFG is currently specialized in the production of IE2,IE3 ,IE4 high efficiency motors , GOST series motors, ML,,YL,YC,MC ,MY

single-phase motors; MS series aluminum shell three-phase motors; Y, Y2 series three-phase asynchronous motor, brake motor,

multi-speed motor, YB3 explosion proof motors etc.

FAQ

Q1:What is your payment term?

Answer: We accept T/T and L/C, paypal.

Q2:What is your MOQ?

Answer: MOQ is 3 Unit.

Q3:What is your lead time?

Answer:Average 3-7days, Except for customized products.

Q4:Do you offer OEM service?

Answer: Yes,we can offer OEM and ODM services.

Q5:What is your wanrranty?

Answer: We offer a 12-month warranty.

Q6:Do you test all your goods before delivery?

Answer: Yes,all our products must undergo strict quality testing before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | 3000rpm,1500rpm,1000rpm,750rpm |

| Number of Stator: | Three-Phase |

| Samples: |

US$ 1365/Unit

1 Unit(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can electric motors be adapted for use in both residential and industrial settings?

Yes, electric motors can be adapted for use in both residential and industrial settings. Their versatility, efficiency, and wide range of power options make them suitable for various applications in both environments. Here’s a detailed explanation of how electric motors can be adapted for use in residential and industrial settings:

- Residential Applications: Electric motors find numerous applications in residential settings, where their compact size, quiet operation, and energy efficiency are highly valued. Some common residential uses of electric motors include:

- Home Appliances: Electric motors power a wide range of home appliances such as refrigerators, washing machines, dishwashers, vacuum cleaners, fans, and air conditioners. These motors are designed to provide efficient and reliable operation while minimizing noise and energy consumption.

- Garage Door Openers: Electric motors are commonly used in residential garage door openers, providing convenient and automated access to the garage.

- HVAC Systems: Electric motors drive the fans and compressors in heating, ventilation, and air conditioning (HVAC) systems, contributing to efficient climate control and indoor comfort.

- Pool Pumps: Electric motors power pool pumps, circulating water and maintaining water quality in residential swimming pools.

- Power Tools: Electric motors are integral components of various power tools used in residential settings, including drills, saws, and trimmers.

- Industrial Applications: Electric motors are extensively used in industrial settings due to their reliability, controllability, and adaptability to various industrial processes. Some common industrial applications of electric motors include:

- Manufacturing Machinery: Electric motors drive a wide range of manufacturing machinery, including conveyor systems, pumps, compressors, mixers, and agitators. These motors are capable of providing precise speed and torque control, enhancing productivity and process efficiency.

- Industrial Fans and Blowers: Electric motors power fans and blowers for ventilation, cooling, and air circulation in industrial facilities, contributing to a comfortable and safe working environment.

- Machine Tools: Electric motors drive machine tools such as lathes, milling machines, and grinders, enabling precision machining operations in industrial manufacturing processes.

- Material Handling Equipment: Electric motors are widely used in material handling equipment such as forklifts, conveyor systems, and hoists, facilitating efficient movement and transportation of goods within industrial facilities.

- Pumps and Compressors: Electric motors power pumps and compressors in industrial applications, such as water supply systems, HVAC systems, and pneumatic systems.

- Adaptability and Customization: Electric motors can be adapted and customized to meet specific requirements in both residential and industrial settings. They are available in a wide range of sizes, power ratings, and configurations to accommodate diverse applications. Motors can be designed for different voltages, frequencies, and environmental conditions, allowing for seamless integration into various systems and equipment. Additionally, advancements in motor control technologies, such as variable frequency drives (VFDs), enable precise speed and torque control, making electric motors highly versatile and adaptable to different operational needs.

- Energy Efficiency and Environmental Benefits: The use of electric motors in both residential and industrial settings offers significant energy efficiency advantages. Electric motors have higher efficiency compared to other types of motors, resulting in reduced energy consumption and operational costs. Furthermore, electric motors produce zero direct emissions at the point of use, contributing to a cleaner and more sustainable environment. In residential settings, energy-efficient electric motors in appliances and HVAC systems help homeowners reduce their energy bills and minimize their carbon footprint. In industrial applications, the adoption of electric motors supports energy conservation initiatives and aligns with sustainability goals.

In summary, electric motors are adaptable for use in both residential and industrial settings. Their compact size, energy efficiency, controllability, and versatility make them suitable for a wide range of applications, from home appliances and garage door openers to manufacturing machinery and material handling equipment. The use of electric motors brings benefits such as improved energy efficiency, reduced emissions, quieter operation, and enhanced control, contributing to the efficiency and sustainability of residential and industrial operations.

How do electric motors contribute to the precision of tasks like robotics?

Electric motors play a critical role in enabling the precision of tasks in robotics. Their unique characteristics and capabilities make them well-suited for precise and controlled movements required in robotic applications. Here’s a detailed explanation of how electric motors contribute to the precision of tasks in robotics:

- Precise Positioning: Electric motors offer precise positioning capabilities, allowing robots to move with accuracy and repeatability. By controlling the motor’s speed, direction, and rotation, robots can achieve precise position control, enabling them to perform tasks with high levels of accuracy. This is particularly important in applications that require precise manipulation, such as assembly tasks, pick-and-place operations, and surgical procedures.

- Speed Control: Electric motors provide precise speed control, allowing robots to perform tasks at varying speeds depending on the requirements. By adjusting the motor’s speed, robots can achieve smooth and controlled movements, which is crucial for tasks that involve delicate handling or interactions with objects or humans. The ability to control motor speed precisely enhances the overall precision and safety of robotic operations.

- Torque Control: Electric motors offer precise torque control, which is essential for tasks that require forceful or delicate interactions. Torque control allows robots to exert the appropriate amount of force or torque, enabling them to handle objects, perform assembly tasks, or execute movements with the required precision. By modulating the motor’s torque output, robots can delicately manipulate objects without causing damage or apply sufficient force for tasks that demand strength.

- Feedback Control Systems: Electric motors in robotics are often integrated with feedback control systems to enhance precision. These systems utilize sensors, such as encoders or resolvers, to provide real-time feedback on the motor’s position, speed, and torque. The feedback information is used to continuously adjust and fine-tune the motor’s performance, compensating for any errors or deviations and ensuring precise movements. The closed-loop nature of feedback control systems allows robots to maintain accuracy and adapt to dynamic environments or changing task requirements.

- Dynamic Response: Electric motors exhibit excellent dynamic response characteristics, enabling quick and precise adjustments to changes in command signals. This responsiveness is particularly advantageous in robotics, where rapid and accurate movements are often required. Electric motors can swiftly accelerate, decelerate, and change direction, allowing robots to perform intricate tasks with precision and efficiency.

- Compact and Lightweight: Electric motors are available in compact and lightweight designs, making them suitable for integration into various robotic systems. Their small size and high power-to-weight ratio allow for efficient utilization of space and minimal impact on the overall weight and size of the robot. This compactness and lightness contribute to the overall precision and maneuverability of robotic platforms.

Electric motors, with their precise positioning, speed control, torque control, feedback control systems, dynamic response, and compactness, significantly contribute to the precision of tasks in robotics. These motors enable robots to execute precise movements, manipulate objects with accuracy, and perform tasks that require high levels of precision. The integration of electric motors with advanced control algorithms and sensory feedback systems empowers robots to adapt to various environments, interact safely with humans, and achieve precise and controlled outcomes in a wide range of robotic applications.

What is an electric motor and how does it function?

An electric motor is a device that converts electrical energy into mechanical energy. It is a common type of motor used in various applications, ranging from household appliances to industrial machinery. Electric motors operate based on the principle of electromagnetism and utilize the interaction between magnetic fields and electric current to generate rotational motion. Here’s a detailed explanation of how an electric motor functions:

- Basic Components: An electric motor consists of several key components. These include a stationary part called the stator, which typically contains one or more coils of wire wrapped around a core, and a rotating part called the rotor, which is connected to an output shaft. The stator and the rotor are often made of magnetic materials.

- Electromagnetic Fields: The stator is supplied with an electric current, which creates a magnetic field around the coils. This magnetic field is typically generated by the flow of direct current (DC) or alternating current (AC) through the coils. The rotor, on the other hand, may have permanent magnets or electromagnets that produce their own magnetic fields.

- Magnetic Interactions: When an electric current flows through the coils in the stator, it generates a magnetic field. The interaction between the magnetic fields of the stator and the rotor causes a rotational force or torque to be exerted on the rotor. The direction of the current and the arrangement of the magnetic fields determine the direction of the rotational motion.

- Electromagnetic Induction: In some types of electric motors, such as induction motors, electromagnetic induction plays a significant role. When alternating current is supplied to the stator, it creates a changing magnetic field that induces voltage in the rotor. This induced voltage generates a current in the rotor, which in turn produces a magnetic field that interacts with the stator’s magnetic field, resulting in rotation.

- Commutation: In motors that use direct current (DC), such as brushed DC motors, an additional component called a commutator is employed. The commutator helps to reverse the direction of the current in the rotor’s electromagnets as the rotor rotates. By periodically reversing the current, the commutator ensures that the magnetic fields of the rotor and the stator are always properly aligned, resulting in continuous rotation.

- Output Shaft: The rotational motion generated by the interaction of the magnetic fields is transferred to the output shaft of the motor. The output shaft is connected to the load, such as a fan blade or a conveyor belt, allowing the mechanical energy produced by the motor to be utilized for various applications.

In summary, an electric motor converts electrical energy into mechanical energy through the interaction of magnetic fields and electric current. By supplying an electric current to the stator, a magnetic field is created, which interacts with the magnetic field of the rotor, causing rotational motion. The type of motor and the arrangement of its components determine the specific operation and characteristics of the motor. Electric motors are widely used in numerous devices and systems, providing efficient and reliable mechanical power for a wide range of applications.

editor by CX 2024-04-30

China best Yr Yzr Wound Rotor Slip Ring Lifting Metallurgy Crane GOST Low Voltage Ball Mill Asynchronous Three Phase AC Induction Electric Motor vacuum pump distributors

Product Description

Product Description

Specifications

YR YZR Wound rotor slip ring Lifting metallurgy crane GOST Low voltage ball mill asynchronous 3 phase ac induction electric motor

slip ring electric YZR motor crane hoist

3kw-250kw

pole:6 8 10

for lifting machine

duty:S1-S5

underground mine motor underground coal mine gear motor ac crane low voltage slip ring wound rotor cement mill re-rolling mill

Feature and usage

YZR,YZ series metallurgical and crane motor

These series of metallurgical and crane 3-phase motor YZR,YZ with wound and squirrel cage rotor are specially used to drive metallurgical crane and other similar machines with better overload capability and mechanical strength,therefore,it is suitable for short time duty or intermittent period duty and equipments with frequent starting and braking or distinct vitration and impact.

The standard range of power output and mounting dimensions are in comply with the reconmended standard of IEC 72,the relation between range of power output and mounting dimensions are similar to standard JEM1202 and West Germany standard DIN42681,so that most of them can be interchanged.

The motor can work well when the altitude does not exceed 1000m.

There are two classes of F and H insulation,Class F is applicalbe to suit temperature which cool air does not exceed 40 under normal condition,Class H is suitable for metallurgical sites when ambient temperature no exceeding 60 both motors have same data.

The motors possess better enclosure,degree of protection IP44 for normal site condition,and IP54 for metallurgical condition.

Motor’s rated voltage and frequency is 380V,50HZ.

Motor Performance

Power range:1.8-250KW

Rated Voltage: 380V-440V

Speed;1500rpm 1000rpm 750rpm 600rpm

Protection Class: IP44 IP54

Ambient Temperature:Ambient temperature not exceeding 40°C (for crane uses) or 60°C (for metallurgical uses)

Altitude: not exceed 1000 Meter

Rated Frequency: 50Hz/60Hz

Insulation Class: F

Temprature rise: B

Cooling:Frame 112-132: IC0041 Frame: 160-355 IC0141 Frame; 400 IC0151

Working Duty: S2,S3,S4,S5

1.Short-time duty type (S2)

Operation of constant load during a given time, less than that required to reach thermal equilibrium, followed by a rest and de-energized period of sufficient duration to re-establish machine temperature within 2 deg K of the coolant.

2. Intermittent periodic duty type (S3)

A sequence of identical duty cycles, each including a period of operation at constant load and a rest and de-energized period but the operation period are so short that it is not sufficient for the machine to reach thermal equilibrium In this duty type, the cycle is such that the starting current does not significantly affect the temperature rise.

3. Intermittent periodic duty type with starting (S4)

A sequence of identical duty cycles, each including a significant period of starting, a period of operation of constant load and a rest and de-energized period, but the operation period are so short that it is not sufficient for the machine to reach thermal equilibrium.

4. Intermittent periodic duty type with electric braking (S5)

A sequence of identical duty cycles, each consisting of a period of starting, a period of operation at constant load and a rest and de-energized period, but the operation period are so short that it is not sufficient for the machine to reach thermal equilibrium.

| IM1 | IM3 | ||||

| Shaft | Mounting | ||||

| height | Arrangement | driving End | Non-driving End | driving End | Non-driving End |

| 112 | 308 | 308 | 308 | 308 | |

| 132 | 309 | 309 | 309 | 309 | |

| 160 | 311 | 311 | 311 | 311 | |

| 180 | 313 | 313 | 313 | 313 | |

| 200 | 315 | 315 | 32315 | 46315 | |

| 225 | 315 | 315 | 32315 | 46315 | |

| 250 | 316 | 316 | 32316 | 46316 | |

| 280 | 32320 | 320 | 32320 | 46320 | |

| 315 | 32322 | 322 | 32322 | 46322 | |

| 355 | 32326 | 326 | |||

| 400 | 32330 | 330 | |||

Company Profile

Certifications

Production Process

Production application

Packaging & Shipping

CHINAMFG Marketing Network

After Sales Service

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Constant Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving |

| Casing Protection: | Closed Type |

| Number of Poles: | 4 |

| Customization: |

Available

|

|

|---|

How does an electric motor ensure efficient energy conversion?

An electric motor ensures efficient energy conversion by employing various design features and principles that minimize energy losses and maximize the conversion of electrical energy into mechanical energy. Here’s a detailed explanation of how electric motors achieve efficient energy conversion:

- Efficient Motor Design: Electric motors are designed with careful consideration given to their construction and materials. High-quality magnetic materials, such as laminated iron cores and permanent magnets, are used to reduce magnetic losses and maximize magnetic field strength. Additionally, the motor’s windings are designed with low-resistance conductors to minimize electrical losses. By optimizing the motor’s design, manufacturers can improve its overall efficiency.

- Reducing Friction and Mechanical Losses: Electric motors are designed to minimize friction and mechanical losses. This is achieved through the use of high-quality bearings and lubrication systems that reduce friction between moving parts. By reducing friction, the motor can operate more efficiently, translating more of the input energy into useful mechanical work rather than dissipating it as heat.