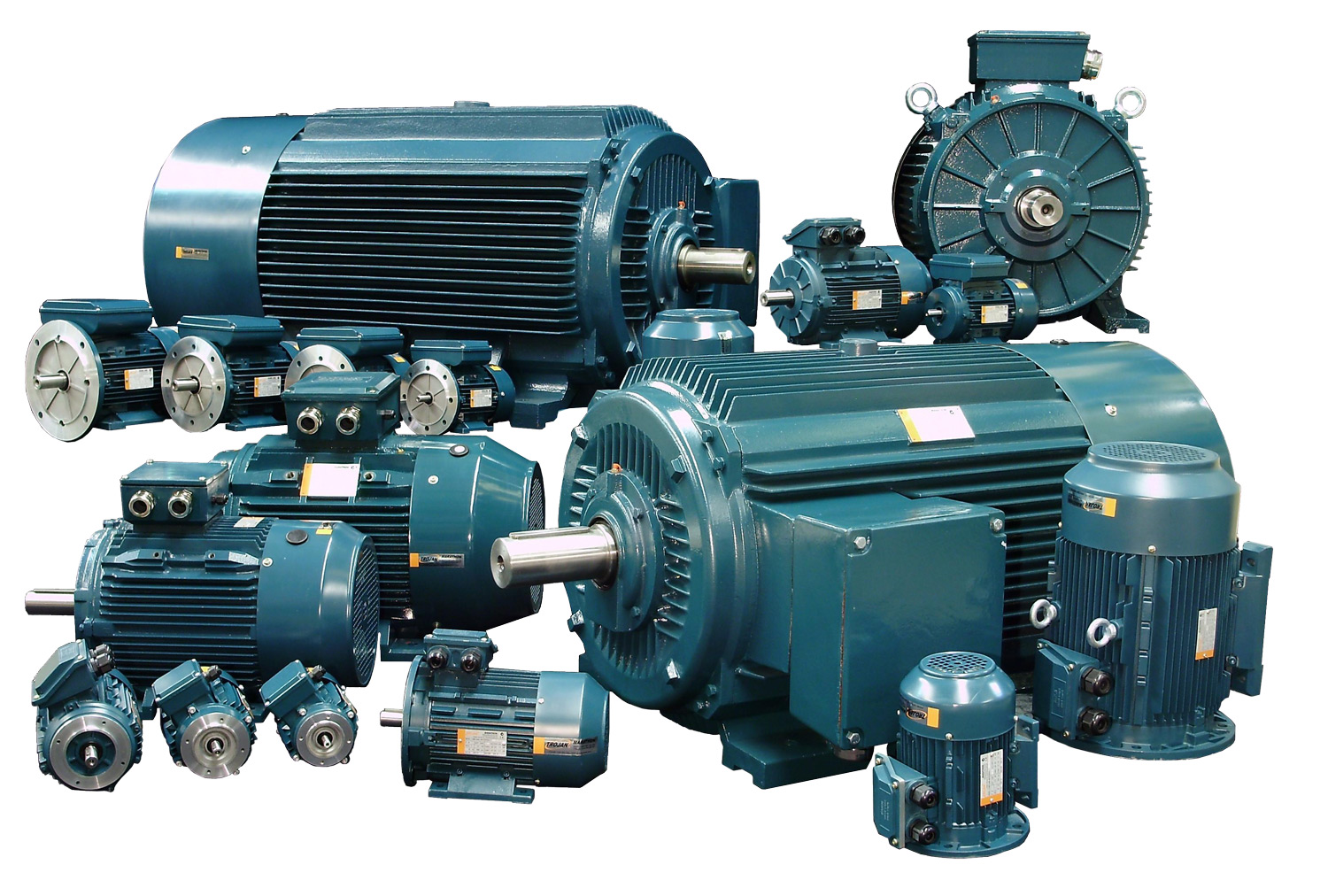

Product Description

Why choose us?

” QUALITY IS OUR CULTURE “

“WITH US YOUR MONEY IN SAFE YOUR BUSINESS IN SAFE”

1.Competitive Advantage Products

2.Full REFUND in case of Bad quality OR Late Delivery

3.Payment By Paypal, Western Union, TT etc we all can accept.

4.Confidentiality Agreement ” Business Secret CONTRACT ”

5.Quality Assurance CONTRACT

6.Small Order Welcomed

MECHANICAL DATA

Packaging & Shipping

1.Export Standard packing which can withstand rough handling.

2.Samples’ delivery time:3-5 working days after we received the deposit.

3.Bulk quantity delivery time: according to the specific quantity.

4. Delivery term: FOB & CIF & CFR & EXW

5. Shipment: your appointed forwarder is acceptable or we send to your Chinese agent

Our Services

Customization and OEM are welcome.

Trade assurance orders are favored.

Other service which you need.

About Us:

HangZhou CHINAMFG Mechanical Electronic Co.,Ltd, establish in 2011, located in Yangtze River CHINAMFG economic

zone, HangZhou City.

We are the factory which gathers production and sales of all kind gas springs and liner actuators. Our mainly

products are all kinds of DC linear actuators, AC linear actuators, servo linear actuators, lift gas springs, lockable

gas springs etc.

Our gas springs and liner actuators are mainly used for all kinds of recliner, massage chair, beds, windows, solar

equipments, cars, buses, furnitures, boats , medical equipment, beauty chairs, aviation, many machines , agriculture

machine equipment and so on.

CHINAMFG has strict quality control system, and full sets of advanced equipment. We have flexible mode of operation,

stable quality, complete catalog, excellent quality. CHINAMFG enjoys a good reputation in domestic and foreign market.

Our product exports to Europe, America, Southeast Asia, the Middle East, Russia, Africa and other countries.

CHINAMFG now is growing and expanding, we have customers throughout the world.

We sincerely hope: Hand in hand, we together create a better future!

The parameters we can customized for you only if you can provide the detail info to us.

If you are interested and want to get more info, please contact me freely.

hax-gasspring

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Single-Phase |

| Samples: |

US$ 290/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide examples of machinery or equipment that rely on electric motors?

Electric motors are extensively used in various machinery and equipment across different industries. They play a crucial role in converting electrical energy into mechanical energy to power a wide range of applications. Here are some examples of machinery and equipment that heavily rely on electric motors:

- Industrial Machinery: Electric motors are found in numerous industrial machinery and equipment, such as pumps, compressors, fans, conveyors, agitators, mixers, and machine tools. These motors provide the necessary power for moving fluids, gases, and materials, as well as driving mechanical processes in manufacturing, mining, construction, and other industrial applications.

- Electric Vehicles: Electric motors are the primary propulsion system in electric vehicles (EVs) and hybrid electric vehicles (HEVs). They provide the power needed to drive the wheels and propel the vehicle. Electric motors in EVs and HEVs offer high efficiency, instant torque, and regenerative braking capabilities, contributing to the advancement of sustainable transportation.

- Household Appliances: Many household appliances rely on electric motors for their operation. Examples include refrigerators, air conditioners, washing machines, dishwashers, vacuum cleaners, blenders, and electric fans. Electric motors enable the movement, cooling, or mechanical functions in these appliances, enhancing convenience and efficiency in daily household tasks.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for various functions. Motors power the fans in air handling units, circulate air through ducts, and drive compressors in air conditioning and refrigeration systems. Electric motors in HVAC systems contribute to efficient temperature control and air circulation in residential, commercial, and industrial buildings.

- Medical Equipment: Electric motors are essential components in a wide array of medical equipment. Examples include MRI machines, X-ray machines, CT scanners, surgical robots, dental drills, infusion pumps, and patient lifts. These motors enable precise movements, imaging capabilities, and mechanical functions in medical devices, supporting diagnostics, treatment, and patient care.

- Power Tools: Electric motors are commonly used in power tools such as drills, saws, grinders, sanders, and routers. They provide the rotational force and power required for cutting, shaping, drilling, and other tasks. Electric motors in power tools offer portability, ease of use, and consistent performance for both professional and DIY applications.

- Aircraft Systems: Electric motors are increasingly utilized in aircraft systems. They power various components, including landing gear actuation systems, fuel pumps, hydraulic systems, and cabin air circulation systems. Electric motors in aircraft contribute to weight reduction, energy efficiency, and improved reliability compared to traditional hydraulic or pneumatic systems.

These examples represent just a fraction of the machinery and equipment that rely on electric motors. From industrial applications to household appliances and transportation systems, electric motors are integral to modern technology, providing efficient and reliable mechanical power for a wide range of purposes.

What safety precautions should be followed when working with electric motors?

Working with electric motors requires adherence to specific safety precautions to ensure the well-being of individuals and prevent accidents. Electric motors involve electrical hazards that can cause electric shock, burns, or other injuries if proper safety measures are not followed. Here’s a detailed explanation of the safety precautions that should be followed when working with electric motors:

- Qualified Personnel: It is important to assign work on electric motors to qualified personnel who have the necessary knowledge, training, and experience in electrical systems and motor operation. Qualified electricians or technicians should handle installation, maintenance, and repairs involving electric motors.

- De-Energization and Lockout/Tagout: Before performing any work on electric motors, they should be de-energized, and appropriate lockout/tagout procedures should be followed. This involves isolating the motor from the power source, ensuring that it cannot be energized accidentally. Lockout/tagout procedures help prevent unexpected startup and protect workers from electrical hazards.

- Personal Protective Equipment (PPE): When working with electric motors, appropriate personal protective equipment should be worn. This may include insulated gloves, safety glasses, protective clothing, and footwear with electrical insulation. PPE helps protect against potential electrical shocks, burns, and other physical hazards.

- Inspection and Maintenance: Regular inspection and maintenance of electric motors are essential to identify potential issues or defects that could compromise safety. This includes checking for loose connections, damaged insulation, worn-out components, or overheating. Any defects or abnormalities should be addressed promptly by qualified personnel.

- Proper Grounding: Electric motors should be properly grounded to prevent electrical shock hazards. Grounding ensures that any fault currents are redirected safely to the ground, reducing the risk of electric shock to individuals working on or around the motor.

- Avoiding Wet Conditions: Electric motors should not be operated or worked on in wet or damp conditions unless they are specifically designed for such environments. Water or moisture increases the risk of electrical shock. If working in wet conditions is necessary, appropriate safety measures and equipment, such as waterproof PPE, should be used.

- Safe Electrical Connections: When connecting or disconnecting electric motors, proper electrical connections should be made. This includes ensuring that power is completely switched off, using appropriate tools and techniques for making connections, and tightening electrical terminals securely. Loose or faulty connections can lead to electrical hazards, overheating, or equipment failure.

- Awareness of Capacitors: Some electric motors contain capacitors that store electrical energy even when the motor is de-energized. These capacitors can discharge unexpectedly and cause electric shock. Therefore, it is important to discharge capacitors safely before working on the motor and to be cautious of potential residual energy even after de-energization.

- Training and Knowledge: Individuals working with electric motors should receive proper training and have a good understanding of electrical safety practices and procedures. They should be knowledgeable about the potential hazards associated with electric motors and know how to respond to emergencies, such as electrical shocks or fires.

- Adherence to Regulations and Standards: Safety precautions should align with relevant regulations, codes, and standards specific to electrical work and motor operation. These may include local electrical codes, occupational safety guidelines, and industry-specific standards. Compliance with these regulations helps ensure a safe working environment.

It is crucial to prioritize safety when working with electric motors. Following these safety precautions, along with any additional guidelines provided by equipment manufacturers or local regulations, helps minimize the risk of electrical accidents, injuries, and property damage. Regular training, awareness, and a safety-focused mindset contribute to a safer working environment when dealing with electric motors.

What is an electric motor and how does it function?

An electric motor is a device that converts electrical energy into mechanical energy. It is a common type of motor used in various applications, ranging from household appliances to industrial machinery. Electric motors operate based on the principle of electromagnetism and utilize the interaction between magnetic fields and electric current to generate rotational motion. Here’s a detailed explanation of how an electric motor functions:

- Basic Components: An electric motor consists of several key components. These include a stationary part called the stator, which typically contains one or more coils of wire wrapped around a core, and a rotating part called the rotor, which is connected to an output shaft. The stator and the rotor are often made of magnetic materials.

- Electromagnetic Fields: The stator is supplied with an electric current, which creates a magnetic field around the coils. This magnetic field is typically generated by the flow of direct current (DC) or alternating current (AC) through the coils. The rotor, on the other hand, may have permanent magnets or electromagnets that produce their own magnetic fields.

- Magnetic Interactions: When an electric current flows through the coils in the stator, it generates a magnetic field. The interaction between the magnetic fields of the stator and the rotor causes a rotational force or torque to be exerted on the rotor. The direction of the current and the arrangement of the magnetic fields determine the direction of the rotational motion.

- Electromagnetic Induction: In some types of electric motors, such as induction motors, electromagnetic induction plays a significant role. When alternating current is supplied to the stator, it creates a changing magnetic field that induces voltage in the rotor. This induced voltage generates a current in the rotor, which in turn produces a magnetic field that interacts with the stator’s magnetic field, resulting in rotation.

- Commutation: In motors that use direct current (DC), such as brushed DC motors, an additional component called a commutator is employed. The commutator helps to reverse the direction of the current in the rotor’s electromagnets as the rotor rotates. By periodically reversing the current, the commutator ensures that the magnetic fields of the rotor and the stator are always properly aligned, resulting in continuous rotation.

- Output Shaft: The rotational motion generated by the interaction of the magnetic fields is transferred to the output shaft of the motor. The output shaft is connected to the load, such as a fan blade or a conveyor belt, allowing the mechanical energy produced by the motor to be utilized for various applications.

In summary, an electric motor converts electrical energy into mechanical energy through the interaction of magnetic fields and electric current. By supplying an electric current to the stator, a magnetic field is created, which interacts with the magnetic field of the rotor, causing rotational motion. The type of motor and the arrangement of its components determine the specific operation and characteristics of the motor. Electric motors are widely used in numerous devices and systems, providing efficient and reliable mechanical power for a wide range of applications.

editor by CX 2024-05-14

China factory Injection Molding Machine Modrol Electric Smm30114013-4W Reb1-Ht 169.6kw Mond Synchronous Servo Motor vacuum pump distributors

Product Description

|

Mond Synchronous servo motor The entire series of AC permanent magnet servo motors use high-performance neodymium Based on motor drive control technology and motor manufacturing technology, we can quickly provide customers with personalized products |

Motor

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Service |

|---|---|

| Warranty: | One Year |

| Machinery Type: | with Reduction Gearbox (136&170rpm) |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What factors should be considered when selecting the right electric motor for a task?

When selecting the right electric motor for a task, several factors need to be considered to ensure optimal performance and compatibility. Here’s a detailed overview of the factors that should be taken into account:

- Load Requirements: The first consideration is understanding the specific load requirements of the task. This includes factors such as the torque or force needed to drive the load, the speed range required, and any variations in load that may occur. By accurately assessing the load requirements, you can determine the appropriate motor type, size, and characteristics needed to handle the task effectively.

- Motor Type: Different motor types are suited for specific applications. Common motor types include AC induction motors, brushless DC motors, brushed DC motors, and stepper motors. Each type has its own advantages and limitations in terms of speed range, torque characteristics, efficiency, control requirements, and cost. Choosing the right motor type depends on the task’s specific requirements and the desired performance.

- Power Supply: Consider the available power supply for the motor. Determine whether the application requires AC or DC power and the voltage and frequency range of the power source. Ensure that the motor’s power requirements align with the available power supply to avoid compatibility issues.

- Efficiency and Energy Consumption: Efficiency is an important factor to consider, especially for applications where energy consumption is a concern. Higher motor efficiency translates to lower energy losses and reduced operating costs over the motor’s lifetime. Look for motors with high efficiency ratings to minimize energy consumption and improve overall system efficiency.

- Environmental Factors: Assess the environmental conditions in which the motor will operate. Consider factors such as temperature, humidity, dust, and vibration. Some motors are specifically designed to withstand harsh environmental conditions, while others may require additional protection or enclosures. Choosing a motor that is suitable for the intended environment will ensure reliable and long-lasting operation.

- Control and Feedback Requirements: Determine whether the application requires precise control over motor speed, position, or torque. Some tasks may benefit from closed-loop control systems that incorporate feedback devices like encoders or sensors to provide accurate motor control. Evaluate the control and feedback requirements of the task and select a motor that is compatible with the desired control mechanism.

- Physical Constraints: Consider any physical constraints or limitations that may impact motor selection. These constraints may include space restrictions, weight limitations, mounting options, and mechanical compatibility with other components or equipment. Ensure that the chosen motor can physically fit and integrate into the system without compromising performance or functionality.

- Cost and Budget: Finally, consider the budget and cost constraints associated with the motor selection. Evaluate the initial purchase cost of the motor as well as the long-term operating costs, including maintenance and energy consumption. Strive to strike a balance between performance and cost-effectiveness to ensure the best value for your specific application.

By considering these factors, you can make an informed decision when selecting the right electric motor for a task. It is crucial to thoroughly analyze the requirements and match them with the motor’s specifications to achieve optimal performance, reliability, and efficiency.

Are there any emerging trends in electric motor technology, such as smart features?

Yes, there are several emerging trends in electric motor technology, including the integration of smart features. These trends aim to improve motor performance, efficiency, and functionality, while also enabling connectivity and advanced control capabilities. Here’s a detailed explanation of some of the emerging trends in electric motor technology:

- Internet of Things (IoT) Integration: Electric motors are becoming increasingly connected as part of the broader IoT ecosystem. IoT integration allows motors to communicate, share data, and be remotely monitored and controlled. By embedding sensors, communication modules, and data analytics capabilities, motors can provide real-time performance data, predictive maintenance insights, and energy consumption information. This connectivity enables proactive maintenance, optimized performance, and enhanced energy efficiency.

- Condition Monitoring and Predictive Maintenance: Smart electric motors are equipped with sensors that monitor various parameters such as temperature, vibration, and current. This data is analyzed in real-time to detect anomalies and potential faults. By implementing predictive maintenance algorithms, motor failures can be anticipated, enabling maintenance activities to be scheduled proactively. This trend reduces unplanned downtime, improves reliability, and optimizes maintenance costs.

- Advanced Motor Control and Optimization: Emerging electric motor technologies focus on advanced motor control techniques and optimization algorithms. These advancements allow for precise control of motor performance, adapting to changing load conditions, and optimizing energy efficiency. Additionally, sophisticated control algorithms enable motor systems to operate in coordination with other equipment, such as variable speed drives, power electronics, and energy storage systems, resulting in improved overall system efficiency.

- Energy Harvesting and Regenerative Features: Electric motors can harness energy through regenerative braking and energy harvesting techniques. Regenerative braking allows motors to recover and convert kinetic energy into electrical energy, which can be fed back into the system or stored for later use. Energy harvesting technologies, such as piezoelectric or electromagnetic systems, can capture ambient energy and convert it into usable electrical energy. These features enhance energy efficiency and reduce overall power consumption.

- Integration with Artificial Intelligence (AI) and Machine Learning (ML): The integration of electric motors with AI and ML technologies enables advanced motor control, optimization, and decision-making capabilities. AI and ML algorithms analyze motor performance data, identify patterns, and make real-time adjustments to optimize efficiency and performance. The combination of AI/ML with electric motors opens up possibilities for autonomous motor control, adaptive energy management, and intelligent fault detection.

- Miniaturization and Lightweight Design: Emerging trends in electric motor technology focus on miniaturization and lightweight design without compromising performance. This trend is particularly relevant for portable devices, electric vehicles, and aerospace applications. Advancements in materials, manufacturing processes, and motor design allow for smaller, lighter, and more powerful motors, enabling greater mobility, improved efficiency, and increased power density.

The integration of smart features in electric motor technology is driving advancements in connectivity, data analytics, predictive maintenance, advanced control, energy harvesting, AI/ML integration, and miniaturization. These trends are revolutionizing the capabilities and functionality of electric motors, making them more intelligent, efficient, and adaptable to various applications. As technology continues to evolve, electric motors are expected to play a crucial role in the ongoing transition towards smart and sustainable industries.

What are the different types of electric motors available?

There are various types of electric motors available, each designed for specific applications and operating principles. These motors differ in their construction, power sources, and performance characteristics. Here is an overview of some common types of electric motors:

- DC Motors: DC (Direct Current) motors are widely used and come in different configurations. The most common types include brushed DC motors and brushless DC motors. Brushed DC motors use brushes and a commutator to switch the direction of current in the rotor, while brushless DC motors use electronic commutation. DC motors offer good speed control and torque characteristics, making them suitable for applications like robotics, electric vehicles, and small appliances.

- AC Motors: AC (Alternating Current) motors are classified into several types, including induction motors, synchronous motors, and universal motors. Induction motors are popular for their simplicity and reliability. They operate based on electromagnetic induction and are commonly used in industrial and residential applications. Synchronous motors operate at a constant speed and are often used in applications that require precise control, such as industrial machinery and synchronous clocks. Universal motors are designed to operate on both AC and DC power sources and are commonly found in household appliances like vacuum cleaners and power tools.

- Stepper Motors: Stepper motors are designed to move in discrete steps or increments, making them suitable for applications that require precise positioning. They are often used in robotics, 3D printers, CNC machines, and other automated systems. Stepper motors are available in various configurations, including permanent magnet stepper motors, variable reluctance stepper motors, and hybrid stepper motors.

- Servo Motors: Servo motors are a type of motor that combines a DC motor with a feedback control mechanism. They are known for their precise control over position, velocity, and acceleration. Servo motors are commonly used in robotics, industrial automation, and applications that require accurate motion control, such as robotic arms, RC vehicles, and camera gimbals.

- Linear Motors: Linear motors are designed to produce linear motion instead of rotational motion. They operate on similar principles as rotary motors but with a different mechanical arrangement. Linear motors find applications in high-speed transportation systems, cutting machines, and other systems that require linear motion without the need for mechanical conversion from rotary to linear motion.

- Haptic Motors: Haptic motors, also known as vibration motors, are small motors used to create tactile feedback or vibrations in electronic devices. They are commonly found in smartphones, game controllers, wearable devices, and other gadgets that require haptic feedback to enhance the user experience.

These are just a few examples of the different types of electric motors available. Each type has its own advantages, limitations, and specific applications. The selection of an electric motor depends on factors such as the required torque, speed, control, efficiency, and the specific needs of the application at hand.

editor by CX 2024-05-14

China high quality Electric Encoder Servo Motor 6es7211-1he40-0xb0 in Stock manufacturer

Product Description

We mainly sell industrial LCD panels, touch screens, plasma panels, HMI, PLC, servo motors and other related machine parts. Our company specializes in selling branded products that can be used in medical equipment, injection molding machines, industrial equipment and other fields. If you need anything please let me know. I will give you super long warranty, lowest price and lowest shipping discount. Our advantages: large inventory, fast delivery, long warranty period, and favorable shipping costs.

Our Advantages

Specific ation

| Iteam | Value |

| Package | Original Packaging |

| Shipping term | TNT DHL FEDEX UPS EMS |

| Quality | High quality |

| Application | Electronic Equipment |

| Payment term | T/T |

| MOQ | 1 PC |

| Delivery time | 1-3working Day |

Company Profile

FAQ

1.Q:How about the warranty ?

A:Yandex provide 12 months warranty for all the goods from us , andyou can refund the goods with any quality problem in 15 days.

2.Q:Other supplier have a better pice than yours.

A.”To create more benefit for clients”is our belief, if you have a better priceplease let Tenroy know , we will try best to meet your price and support you.

3.Q:What can you buy from us?

A:Electronic components,IC,CHIP,Single chip microcomputer,integrated circuit

4.Q:We have not cooperation before , how we can believe you ?

A:For our first order , you can pay after we prepare the goods.

5.Q:What about shipment?

A:We have DHL forwarder with competitive price , of course , cutsomerscan also use their own freight forwarders

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Boat |

|---|---|

| Speed: | Low Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 6 |

| Customization: |

Available

|

|

|---|

How does an electric motor ensure efficient energy conversion?

An electric motor ensures efficient energy conversion by employing various design features and principles that minimize energy losses and maximize the conversion of electrical energy into mechanical energy. Here’s a detailed explanation of how electric motors achieve efficient energy conversion:

- Efficient Motor Design: Electric motors are designed with careful consideration given to their construction and materials. High-quality magnetic materials, such as laminated iron cores and permanent magnets, are used to reduce magnetic losses and maximize magnetic field strength. Additionally, the motor’s windings are designed with low-resistance conductors to minimize electrical losses. By optimizing the motor’s design, manufacturers can improve its overall efficiency.

- Reducing Friction and Mechanical Losses: Electric motors are designed to minimize friction and mechanical losses. This is achieved through the use of high-quality bearings and lubrication systems that reduce friction between moving parts. By reducing friction, the motor can operate more efficiently, translating more of the input energy into useful mechanical work rather than dissipating it as heat.

- Efficient Control and Power Electronics: Electric motors employ advanced control techniques and power electronics to enhance energy conversion efficiency. Variable frequency drives (VFDs) are commonly used to control motor speed and torque, allowing the motor to operate at optimal efficiency levels under varying load conditions. Power electronics devices, such as insulated gate bipolar transistors (IGBTs) and MOSFETs, minimize switching losses and optimize power flow within the motor.

- Regenerative Braking and Energy Recovery: Some electric motors, particularly those used in hybrid electric vehicles (HEVs) and electric trains, incorporate regenerative braking systems. These systems convert the kinetic energy of the moving vehicle back into electrical energy, which can be stored and reused. By capturing and reusing energy that would otherwise be wasted as heat during braking, regenerative braking significantly improves overall energy efficiency.

- Efficient Cooling and Thermal Management: Electric motors generate heat during operation, and excessive heat can lead to energy losses and reduced efficiency. To mitigate this, motors are designed with efficient cooling systems such as fans, heat sinks, or liquid cooling methods. Proper thermal management ensures that the motor operates within the optimal temperature range, reducing losses and improving overall efficiency.

- High-Efficiency Standards and Regulations: Governments and organizations have established energy efficiency standards and regulations for electric motors. These standards encourage manufacturers to produce motors with higher efficiency ratings. Compliance with these standards ensures that motors meet certain efficiency criteria, resulting in improved energy conversion and reduced energy consumption.

By incorporating these design features, control techniques, and efficiency measures, electric motors achieve efficient energy conversion. They minimize energy losses due to factors such as resistance, friction, and heat dissipation, ensuring that a significant portion of the input electrical energy is converted into useful mechanical work. The continuous advancements in motor design, materials, and control technologies further contribute to improving the overall energy efficiency of electric motors.

How do electric motors impact the overall productivity of manufacturing processes?

Electric motors have a significant impact on the overall productivity of manufacturing processes. Their versatility, reliability, and efficiency make them essential components in a wide range of industrial applications. Here’s a detailed explanation of how electric motors contribute to enhancing productivity in manufacturing:

- Mechanization and Automation: Electric motors serve as the primary power source for a vast array of industrial machinery and equipment. By providing mechanical power, electric motors enable mechanization and automation of manufacturing processes. They drive conveyor belts, pumps, compressors, robots, and other machinery, allowing for efficient material handling, assembly, and production operations. The use of electric motors in mechanized and automated systems reduces manual labor, accelerates production rates, and improves overall productivity.

- Precise Control and Repeatable Movements: Electric motors offer precise control over speed, position, and torque, enabling accurate and repeatable movements in manufacturing processes. This precision is crucial for tasks that require consistent and controlled operations, such as precision cutting, drilling, machining, and assembly. Electric motors allow for fine adjustments and control, ensuring that manufacturing operations are performed with high levels of accuracy and repeatability, which ultimately enhances productivity and product quality.

- High Speed and Acceleration: Electric motors are capable of achieving high rotational speeds and rapid acceleration, enabling fast-paced manufacturing processes. Motors with high-speed capabilities are utilized in applications that require quick operations, such as high-speed machining, packaging, and sorting. The ability of electric motors to rapidly accelerate and decelerate facilitates efficient cycle times and overall process throughput, contributing to increased productivity.

- Reliability and Durability: Electric motors are known for their reliability and durability, making them well-suited for demanding manufacturing environments. With proper maintenance, electric motors can operate continuously for extended periods, minimizing downtime due to motor failures. The reliability of electric motors ensures consistent and uninterrupted production, optimizing manufacturing productivity and reducing costly disruptions.

- Energy Efficiency: Electric motors have witnessed significant advancements in energy efficiency, leading to reduced energy consumption in manufacturing processes. Energy-efficient motors convert a higher percentage of electrical input power into useful mechanical output power, resulting in lower energy costs. By utilizing energy-efficient electric motors, manufacturers can achieve cost savings and improve the overall sustainability of their operations. Additionally, energy-efficient motors generate less heat, reducing the need for cooling and improving the overall efficiency of auxiliary systems.

- Integration with Control Systems: Electric motors can be seamlessly integrated with sophisticated control systems and automation technologies. This integration allows for centralized control, monitoring, and optimization of manufacturing processes. Control systems can regulate motor speed, torque, and performance based on real-time data, enabling adaptive and efficient operations. The integration of electric motors with control systems enhances the overall productivity by optimizing process parameters, minimizing errors, and facilitating seamless coordination between different stages of manufacturing.

Electric motors significantly impact the overall productivity of manufacturing processes by enabling mechanization, automation, precise control, high-speed operations, reliability, energy efficiency, and integration with advanced control systems. Their versatility and performance characteristics make them indispensable in a wide range of industries, including automotive, electronics, aerospace, food processing, and more. By harnessing the power of electric motors, manufacturers can streamline operations, improve product quality, increase throughput, and ultimately enhance productivity in their manufacturing processes.

What are the different types of electric motors available?

There are various types of electric motors available, each designed for specific applications and operating principles. These motors differ in their construction, power sources, and performance characteristics. Here is an overview of some common types of electric motors:

- DC Motors: DC (Direct Current) motors are widely used and come in different configurations. The most common types include brushed DC motors and brushless DC motors. Brushed DC motors use brushes and a commutator to switch the direction of current in the rotor, while brushless DC motors use electronic commutation. DC motors offer good speed control and torque characteristics, making them suitable for applications like robotics, electric vehicles, and small appliances.

- AC Motors: AC (Alternating Current) motors are classified into several types, including induction motors, synchronous motors, and universal motors. Induction motors are popular for their simplicity and reliability. They operate based on electromagnetic induction and are commonly used in industrial and residential applications. Synchronous motors operate at a constant speed and are often used in applications that require precise control, such as industrial machinery and synchronous clocks. Universal motors are designed to operate on both AC and DC power sources and are commonly found in household appliances like vacuum cleaners and power tools.

- Stepper Motors: Stepper motors are designed to move in discrete steps or increments, making them suitable for applications that require precise positioning. They are often used in robotics, 3D printers, CNC machines, and other automated systems. Stepper motors are available in various configurations, including permanent magnet stepper motors, variable reluctance stepper motors, and hybrid stepper motors.

- Servo Motors: Servo motors are a type of motor that combines a DC motor with a feedback control mechanism. They are known for their precise control over position, velocity, and acceleration. Servo motors are commonly used in robotics, industrial automation, and applications that require accurate motion control, such as robotic arms, RC vehicles, and camera gimbals.

- Linear Motors: Linear motors are designed to produce linear motion instead of rotational motion. They operate on similar principles as rotary motors but with a different mechanical arrangement. Linear motors find applications in high-speed transportation systems, cutting machines, and other systems that require linear motion without the need for mechanical conversion from rotary to linear motion.

- Haptic Motors: Haptic motors, also known as vibration motors, are small motors used to create tactile feedback or vibrations in electronic devices. They are commonly found in smartphones, game controllers, wearable devices, and other gadgets that require haptic feedback to enhance the user experience.

These are just a few examples of the different types of electric motors available. Each type has its own advantages, limitations, and specific applications. The selection of an electric motor depends on factors such as the required torque, speed, control, efficiency, and the specific needs of the application at hand.

editor by CX 2024-05-09

China Good quality Injection Molding Machine Modrol Electric Smm3076215-4f Reb1-H3 115kw Mond Synchronous Servo Motor vacuum pump ac

Product Description

|

Mond Synchronous servo motor The entire series of AC permanent magnet servo motors use high-performance neodymium Based on motor drive control technology and motor manufacturing technology, we can quickly provide customers with personalized products |

Motor

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Service |

|---|---|

| Warranty: | One Year |

| Machinery Type: | Air-Cooled Vertical |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide examples of machinery or equipment that rely on electric motors?

Electric motors are extensively used in various machinery and equipment across different industries. They play a crucial role in converting electrical energy into mechanical energy to power a wide range of applications. Here are some examples of machinery and equipment that heavily rely on electric motors:

- Industrial Machinery: Electric motors are found in numerous industrial machinery and equipment, such as pumps, compressors, fans, conveyors, agitators, mixers, and machine tools. These motors provide the necessary power for moving fluids, gases, and materials, as well as driving mechanical processes in manufacturing, mining, construction, and other industrial applications.

- Electric Vehicles: Electric motors are the primary propulsion system in electric vehicles (EVs) and hybrid electric vehicles (HEVs). They provide the power needed to drive the wheels and propel the vehicle. Electric motors in EVs and HEVs offer high efficiency, instant torque, and regenerative braking capabilities, contributing to the advancement of sustainable transportation.

- Household Appliances: Many household appliances rely on electric motors for their operation. Examples include refrigerators, air conditioners, washing machines, dishwashers, vacuum cleaners, blenders, and electric fans. Electric motors enable the movement, cooling, or mechanical functions in these appliances, enhancing convenience and efficiency in daily household tasks.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for various functions. Motors power the fans in air handling units, circulate air through ducts, and drive compressors in air conditioning and refrigeration systems. Electric motors in HVAC systems contribute to efficient temperature control and air circulation in residential, commercial, and industrial buildings.

- Medical Equipment: Electric motors are essential components in a wide array of medical equipment. Examples include MRI machines, X-ray machines, CT scanners, surgical robots, dental drills, infusion pumps, and patient lifts. These motors enable precise movements, imaging capabilities, and mechanical functions in medical devices, supporting diagnostics, treatment, and patient care.

- Power Tools: Electric motors are commonly used in power tools such as drills, saws, grinders, sanders, and routers. They provide the rotational force and power required for cutting, shaping, drilling, and other tasks. Electric motors in power tools offer portability, ease of use, and consistent performance for both professional and DIY applications.

- Aircraft Systems: Electric motors are increasingly utilized in aircraft systems. They power various components, including landing gear actuation systems, fuel pumps, hydraulic systems, and cabin air circulation systems. Electric motors in aircraft contribute to weight reduction, energy efficiency, and improved reliability compared to traditional hydraulic or pneumatic systems.

These examples represent just a fraction of the machinery and equipment that rely on electric motors. From industrial applications to household appliances and transportation systems, electric motors are integral to modern technology, providing efficient and reliable mechanical power for a wide range of purposes.

What advancements in electric motor technology have improved energy efficiency?

Advancements in electric motor technology have played a crucial role in improving energy efficiency, leading to more sustainable and environmentally friendly applications. Here’s a detailed explanation of some key advancements in electric motor technology that have contributed to enhanced energy efficiency:

- High-Efficiency Motor Designs: One significant advancement in electric motor technology is the development of high-efficiency motor designs. These designs focus on reducing energy losses during motor operation, resulting in improved overall efficiency. High-efficiency motors are engineered with optimized stator and rotor geometries, reduced core losses, and improved magnetic materials. These design enhancements minimize energy wastage and increase the motor’s efficiency, allowing it to convert a higher percentage of electrical input power into useful mechanical output power.

- Premium Efficiency Standards: Another notable advancement is the establishment and adoption of premium efficiency standards for electric motors. These standards, such as the International Electrotechnical Commission (IEC) IE3 and NEMA Premium efficiency standards, set minimum efficiency requirements for motors. Manufacturers strive to meet or exceed these standards by incorporating innovative technologies and design features that enhance energy efficiency. The implementation of premium efficiency standards has led to the widespread availability of more efficient motors in the market, encouraging energy-conscious choices and reducing energy consumption in various applications.

- Variable Speed Drives: Electric motor systems often operate under varying load conditions, and traditional motor designs operate at a fixed speed. However, the development and adoption of variable speed drives (VSDs) have revolutionized motor efficiency. VSDs, such as frequency converters or inverters, allow the motor’s speed to be adjusted according to the load requirements. By operating motors at the optimal speed for each task, VSDs minimize energy losses and significantly improve energy efficiency. This technology is particularly beneficial in applications with variable loads, such as HVAC systems, pumps, and conveyors.

- Improved Motor Control and Control Algorithms: Advanced motor control techniques and algorithms have contributed to improved energy efficiency. These control systems employ sophisticated algorithms to optimize motor performance, including speed control, torque control, and power factor correction. By precisely adjusting motor parameters based on real-time operating conditions, these control systems minimize energy losses and maximize motor efficiency. Additionally, the integration of sensor technology and feedback loops enables closed-loop control, allowing motors to respond dynamically and adaptively to changes in load demand, further enhancing energy efficiency.

- Use of Permanent Magnet Motors: Permanent magnet (PM) motors have gained popularity due to their inherent high energy efficiency. PM motors utilize permanent magnets in the rotor, eliminating the need for rotor windings and reducing rotor losses. This design enables PM motors to achieve higher power densities, improved efficiency, and enhanced performance compared to traditional induction motors. The use of PM motors is particularly prevalent in applications where high efficiency and compact size are critical, such as electric vehicles, appliances, and industrial machinery.

- Integration of Advanced Materials: Advances in materials science have contributed to improved motor efficiency. The utilization of advanced magnetic materials, such as rare-earth magnets, allows for stronger and more efficient magnetic fields, resulting in higher motor efficiency. Additionally, the development of low-loss electrical steel laminations and improved insulation materials reduces core losses and minimizes energy wastage. These advanced materials enhance the overall efficiency of electric motors, making them more energy-efficient and environmentally friendly.

The advancements in electric motor technology, including high-efficiency motor designs, premium efficiency standards, variable speed drives, improved motor control, permanent magnet motors, and advanced materials, have collectively driven significant improvements in energy efficiency. These advancements have led to more efficient motor systems, reduced energy consumption, and increased sustainability across a wide range of applications, including industrial machinery, transportation, HVAC systems, appliances, and renewable energy systems.

What industries and applications commonly use electric motors?

Electric motors are widely utilized in various industries and applications due to their versatility, efficiency, and controllability. Here’s a detailed overview of the industries and applications where electric motors are commonly employed:

- Industrial Manufacturing: Electric motors are extensively used in industrial manufacturing processes. They power machinery and equipment such as conveyor systems, pumps, compressors, fans, mixers, robots, and assembly line equipment. Electric motors provide efficient and precise control over motion, making them essential for mass production and automation.

- Transportation: Electric motors play a crucial role in the transportation sector. They are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) to drive the wheels, providing propulsion. Electric motors offer benefits such as high torque at low speeds, regenerative braking, and improved energy efficiency. They are also employed in trains, trams, ships, and aircraft for various propulsion and auxiliary systems.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for air circulation, fans, blowers, and pumps. Electric motors help in maintaining comfortable indoor environments and ensure efficient cooling, heating, and ventilation in residential, commercial, and industrial buildings.

- Appliances and Household Devices: Electric motors are found in numerous household appliances and devices. They power refrigerators, washing machines, dryers, dishwashers, vacuum cleaners, blenders, food processors, air conditioners, ceiling fans, and many other appliances. Electric motors enable the necessary mechanical actions for these devices to function effectively.

- Renewable Energy: Electric motors are integral components of renewable energy systems. They are used in wind turbines to convert wind energy into electrical energy. Electric motors are also employed in solar tracking systems to orient solar panels towards the sun for optimal energy capture. Additionally, electric motors are utilized in hydroelectric power plants for controlling water flow and generating electricity.

- Medical Equipment: Electric motors are crucial in various medical devices and equipment. They power surgical tools, pumps for drug delivery and fluid management, diagnostic equipment, dental drills, patient lifts, wheelchair propulsion, and many other medical devices. Electric motors provide the necessary precision, control, and reliability required in healthcare settings.

- Robotics and Automation: Electric motors are extensively used in robotics and automation applications. They drive the joints and actuators of robots, enabling precise and controlled movement. Electric motors are also employed in automated systems for material handling, assembly, packaging, and quality control in industries such as automotive manufacturing, electronics, and logistics.

- Aerospace and Defense: Electric motors have significant applications in the aerospace and defense sectors. They are used in aircraft for propulsion, control surfaces, landing gear, and auxiliary systems. Electric motors are also employed in military equipment, drones, satellites, guided missiles, and underwater vehicles.

These are just a few examples of the industries and applications where electric motors are commonly used. Electric motors provide a reliable, efficient, and controllable means of converting electrical energy into mechanical energy, making them essential components in numerous technologies and systems across various sectors.

editor by CX 2024-05-08

China wholesaler Injection Molding Machine Modrol Electric Smm1820215-4W Reb1-H3 29.1kw Mond Synchronous Servo Motor vacuum pump oil near me

Product Description

|

Mond Synchronous servo motor The entire series of AC permanent magnet servo motors use high-performance neodymium Based on motor drive control technology and motor manufacturing technology, we can quickly provide customers with personalized products |

Motor

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Service |

|---|---|

| Warranty: | One Year |

| Machinery Type: | Oil-Cooled Vertical |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do electric motors contribute to the efficiency of tasks like transportation?

Electric motors play a significant role in enhancing the efficiency of various transportation tasks. Their unique characteristics and advantages contribute to improved performance, reduced energy consumption, and environmental benefits. Here’s a detailed explanation of how electric motors contribute to the efficiency of tasks like transportation:

- High Energy Conversion Efficiency: Electric motors are known for their high energy conversion efficiency. They can convert a large percentage of electrical energy supplied to them into mechanical energy, resulting in minimal energy losses. Compared to internal combustion engines (ICEs), electric motors can achieve significantly higher efficiencies, which translates to improved energy utilization and reduced fuel consumption.

- Instant Torque and Responsive Performance: Electric motors deliver instant torque, providing quick acceleration and responsive performance. This characteristic is particularly advantageous in transportation tasks, such as electric vehicles (EVs) and electric trains, where rapid acceleration and deceleration are required. The immediate response of electric motors enhances overall vehicle efficiency and driver experience.

- Regenerative Braking: Electric motors enable regenerative braking, a process where the motor acts as a generator to convert kinetic energy into electrical energy during deceleration or braking. This recovered energy is then stored in batteries or fed back into the power grid, reducing energy waste and extending the vehicle’s range. Regenerative braking improves overall efficiency and helps maximize the energy efficiency of electric vehicles.

- Efficient Power Distribution: Electric motors in transportation systems can be powered by electricity generated from various sources, including renewable energy. This allows for a diversified and cleaner energy mix, contributing to reduced greenhouse gas emissions and environmental impact. By utilizing electric motors, transportation tasks can leverage the increasing availability of renewable energy resources, leading to a more sustainable and efficient transport ecosystem.

- Reduced Maintenance Requirements: Electric motors have fewer moving parts compared to ICEs, resulting in reduced maintenance requirements. They eliminate the need for components like spark plugs, fuel injection systems, and complex exhaust systems. As a result, electric motors typically have longer service intervals, lower maintenance costs, and reduced downtime. This enhances operational efficiency and reduces the overall maintenance burden in transportation applications.

- Quiet and Vibration-Free Operation: Electric motors operate quietly and produce minimal vibrations compared to ICEs. This characteristic contributes to a more comfortable and pleasant passenger experience, especially in electric vehicles and electric trains. The reduced noise and vibration levels enhance the overall efficiency and comfort of transportation tasks while minimizing noise pollution in urban environments.

- Efficient Power Management and Control: Electric motors can be integrated with advanced power management and control systems. This allows for precise control over motor speed, torque, and power output, optimizing efficiency for specific transportation tasks. Intelligent control algorithms and energy management systems can further enhance the efficiency of electric motors by dynamically adjusting power delivery based on demand, driving conditions, and energy availability.

- Reduction of Emissions and Environmental Impact: Electric motors contribute to significant reductions in emissions and environmental impact compared to traditional combustion engines. By eliminating direct emissions at the point of use, electric motors help improve air quality and reduce greenhouse gas emissions. When powered by renewable energy sources, electric motors enable nearly zero-emission transportation, paving the way for a cleaner and more sustainable transportation sector.

Through their high energy conversion efficiency, instant torque, regenerative braking, efficient power distribution, reduced maintenance requirements, quiet operation, efficient power management, and environmental benefits, electric motors significantly enhance the efficiency of tasks like transportation. The widespread adoption of electric motors in transportation systems has the potential to revolutionize the industry, promoting energy efficiency, reducing reliance on fossil fuels, and mitigating environmental impact.

Can electric motors be used in renewable energy systems like wind turbines?

Yes, electric motors can be used in renewable energy systems like wind turbines. In fact, electric motors play a crucial role in converting the kinetic energy of the wind into electrical energy in wind turbines. Here’s a detailed explanation of how electric motors are utilized in wind turbines and their role in renewable energy systems:

Wind turbines are designed to capture the energy from the wind and convert it into electrical power. Electric motors are used in wind turbines to drive the rotation of the turbine blades and generate electricity through the following process:

- Wind Capture: The wind turbine blades are designed to efficiently capture the kinetic energy of the wind. As the wind blows, it causes the blades to rotate.

- Blade Rotation: The rotational motion of the turbine blades is achieved through electric motors known as pitch motors. Pitch motors adjust the angle or pitch of the blades to optimize their orientation relative to the wind direction. The electric motors drive the mechanical mechanism that rotates the blades, allowing them to capture the maximum energy from the wind.

- Power Generation: The rotation of the wind turbine blades drives the main shaft of the turbine, which is connected to an electric generator. The generator consists of another electric motor known as the generator motor or generator rotor. The rotational motion of the generator rotor within a magnetic field induces an electrical current in the generator’s stator windings, producing electricity.

- Power Conversion and Distribution: The electricity generated by the wind turbine’s generator motor is typically in the form of alternating current (AC). To make it compatible with the electrical grid or local power system, the AC power is converted to the appropriate voltage and frequency using power electronics such as inverters. These power electronics may also incorporate electric motors for various conversion and control functions.

- Integration with Renewable Energy Systems: Wind turbines, equipped with electric motors, are integrated into renewable energy systems to contribute to the generation of clean and sustainable power. Multiple wind turbines can be connected together to form wind farms, which collectively generate significant amounts of electricity. The electricity produced by wind turbines can be fed into the electrical grid, used to power local communities, or stored in energy storage systems for later use.

Electric motors in wind turbines enable the efficient conversion of wind energy into electrical energy, making wind power a viable and renewable energy source. The advancements in motor and generator technologies, along with control systems and power electronics, have enhanced the performance, reliability, and overall efficiency of wind turbines. Additionally, electric motors allow for precise control and adjustment of the turbine blades, optimizing the energy capture and minimizing the impact of varying wind conditions.

Overall, the use of electric motors in wind turbines is instrumental in harnessing the power of wind and contributing to the generation of clean and sustainable energy in renewable energy systems.

What is an electric motor and how does it function?

An electric motor is a device that converts electrical energy into mechanical energy. It is a common type of motor used in various applications, ranging from household appliances to industrial machinery. Electric motors operate based on the principle of electromagnetism and utilize the interaction between magnetic fields and electric current to generate rotational motion. Here’s a detailed explanation of how an electric motor functions:

- Basic Components: An electric motor consists of several key components. These include a stationary part called the stator, which typically contains one or more coils of wire wrapped around a core, and a rotating part called the rotor, which is connected to an output shaft. The stator and the rotor are often made of magnetic materials.

- Electromagnetic Fields: The stator is supplied with an electric current, which creates a magnetic field around the coils. This magnetic field is typically generated by the flow of direct current (DC) or alternating current (AC) through the coils. The rotor, on the other hand, may have permanent magnets or electromagnets that produce their own magnetic fields.

- Magnetic Interactions: When an electric current flows through the coils in the stator, it generates a magnetic field. The interaction between the magnetic fields of the stator and the rotor causes a rotational force or torque to be exerted on the rotor. The direction of the current and the arrangement of the magnetic fields determine the direction of the rotational motion.

- Electromagnetic Induction: In some types of electric motors, such as induction motors, electromagnetic induction plays a significant role. When alternating current is supplied to the stator, it creates a changing magnetic field that induces voltage in the rotor. This induced voltage generates a current in the rotor, which in turn produces a magnetic field that interacts with the stator’s magnetic field, resulting in rotation.

- Commutation: In motors that use direct current (DC), such as brushed DC motors, an additional component called a commutator is employed. The commutator helps to reverse the direction of the current in the rotor’s electromagnets as the rotor rotates. By periodically reversing the current, the commutator ensures that the magnetic fields of the rotor and the stator are always properly aligned, resulting in continuous rotation.

- Output Shaft: The rotational motion generated by the interaction of the magnetic fields is transferred to the output shaft of the motor. The output shaft is connected to the load, such as a fan blade or a conveyor belt, allowing the mechanical energy produced by the motor to be utilized for various applications.

In summary, an electric motor converts electrical energy into mechanical energy through the interaction of magnetic fields and electric current. By supplying an electric current to the stator, a magnetic field is created, which interacts with the magnetic field of the rotor, causing rotational motion. The type of motor and the arrangement of its components determine the specific operation and characteristics of the motor. Electric motors are widely used in numerous devices and systems, providing efficient and reliable mechanical power for a wide range of applications.

editor by CX 2024-04-25

China Custom 850W Electric Servo Motor Integral Design Factory Supply Directly vacuum pump ac

Product Description

>>> V7E Series Servo Motor Overview

VEICHI V7E Series Servo Motor is used together with the newly upgraded SD700 servo drive. Excellent performance design enables our motors to be widely used in various industrial fields, such as machine tools, packaging industry, industrial robots, and so on.

1. Cost-effective

2. Better out

3. Lower temperature rise

4. Higher precision

5. Shorter length

6. Better protection

>>> Full range of motor body IP67 protection grade, more durable

The protection level of the whole series of V7E motors has reached the level of IP67. The high protection level can make the motor suitable for more environments, so that the motor has a longer operating life and the protection level has reached the highest standard in the industry.

Dust and gas cannot enter, and all gaps have rubber parts to ensure reliable air tightness.

A forceful spray of water from any direction on the enclosure will have no deleterious effect.

Under normal temperature and pressure, there will be no harmful effects when the shell is temporarily immersed in water at a depth of 1M.

>>> No lead wires, more beautiful

The V7E motor adopts aerial plug-in wiring, no lead wires, integrated end cover, and fewer holes for screws on the front cover. On the whole, the motor is simpler and more beautiful.

>>> The temperature rise of the motor is lower, which is more friendly to the equipment

The temperature rise of the V7E motor has been greatly improved. Compared with the VM7 motor, the overall temperature rise has dropped by 5-10 °C. (750W motor)

>>> Less shaft runout and higher accuracy

The shaft runout of the V7E motor is smaller, and the precision is higher, which can challenge higher-end applications. From the original 4-wire shaft jump accuracy to 2-wire shaft jump accuracy, it belongs to the cutting-edge level in the industry.

>>> Shorter motor, wider application range

With the increasing integration of automation equipment, the installation space is getting smaller and smaller. In order to adapt to this trend, our V7E motor is made shorter, which can be applied to more industries that require motor length.

>>> Differences between V7E motor and VM7 motor wire

1. 40/60/80 flange VM7 motor is replaced by V7E motor without replacing the original wire, but additional wiring can be added;

2. 110 and above flange motors can be switched seamlessly without adapter wires.

>>> Industrial Applications for V7E Series Servo Motor

Applications: Electronic manufacturing equipment, numerical control equipment, packaging machinery, printing machinery, textile machinery, plastic machinery and glass equipment, testing equipment, etc.

>>> About VEICHI

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machine Tool |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Three-Phase |

| Function: | Control |

| Casing Protection: | Open Type |

| Number of Poles: | 10 |

| Customization: |

Available

|

|

|---|

How do electric motors contribute to the efficiency of tasks like transportation?

Electric motors play a significant role in enhancing the efficiency of various transportation tasks. Their unique characteristics and advantages contribute to improved performance, reduced energy consumption, and environmental benefits. Here’s a detailed explanation of how electric motors contribute to the efficiency of tasks like transportation:

- High Energy Conversion Efficiency: Electric motors are known for their high energy conversion efficiency. They can convert a large percentage of electrical energy supplied to them into mechanical energy, resulting in minimal energy losses. Compared to internal combustion engines (ICEs), electric motors can achieve significantly higher efficiencies, which translates to improved energy utilization and reduced fuel consumption.

- Instant Torque and Responsive Performance: Electric motors deliver instant torque, providing quick acceleration and responsive performance. This characteristic is particularly advantageous in transportation tasks, such as electric vehicles (EVs) and electric trains, where rapid acceleration and deceleration are required. The immediate response of electric motors enhances overall vehicle efficiency and driver experience.

- Regenerative Braking: Electric motors enable regenerative braking, a process where the motor acts as a generator to convert kinetic energy into electrical energy during deceleration or braking. This recovered energy is then stored in batteries or fed back into the power grid, reducing energy waste and extending the vehicle’s range. Regenerative braking improves overall efficiency and helps maximize the energy efficiency of electric vehicles.

- Efficient Power Distribution: Electric motors in transportation systems can be powered by electricity generated from various sources, including renewable energy. This allows for a diversified and cleaner energy mix, contributing to reduced greenhouse gas emissions and environmental impact. By utilizing electric motors, transportation tasks can leverage the increasing availability of renewable energy resources, leading to a more sustainable and efficient transport ecosystem.

- Reduced Maintenance Requirements: Electric motors have fewer moving parts compared to ICEs, resulting in reduced maintenance requirements. They eliminate the need for components like spark plugs, fuel injection systems, and complex exhaust systems. As a result, electric motors typically have longer service intervals, lower maintenance costs, and reduced downtime. This enhances operational efficiency and reduces the overall maintenance burden in transportation applications.

- Quiet and Vibration-Free Operation: Electric motors operate quietly and produce minimal vibrations compared to ICEs. This characteristic contributes to a more comfortable and pleasant passenger experience, especially in electric vehicles and electric trains. The reduced noise and vibration levels enhance the overall efficiency and comfort of transportation tasks while minimizing noise pollution in urban environments.

- Efficient Power Management and Control: Electric motors can be integrated with advanced power management and control systems. This allows for precise control over motor speed, torque, and power output, optimizing efficiency for specific transportation tasks. Intelligent control algorithms and energy management systems can further enhance the efficiency of electric motors by dynamically adjusting power delivery based on demand, driving conditions, and energy availability.

- Reduction of Emissions and Environmental Impact: Electric motors contribute to significant reductions in emissions and environmental impact compared to traditional combustion engines. By eliminating direct emissions at the point of use, electric motors help improve air quality and reduce greenhouse gas emissions. When powered by renewable energy sources, electric motors enable nearly zero-emission transportation, paving the way for a cleaner and more sustainable transportation sector.

Through their high energy conversion efficiency, instant torque, regenerative braking, efficient power distribution, reduced maintenance requirements, quiet operation, efficient power management, and environmental benefits, electric motors significantly enhance the efficiency of tasks like transportation. The widespread adoption of electric motors in transportation systems has the potential to revolutionize the industry, promoting energy efficiency, reducing reliance on fossil fuels, and mitigating environmental impact.

Can electric motors be used in renewable energy systems like wind turbines?

Yes, electric motors can be used in renewable energy systems like wind turbines. In fact, electric motors play a crucial role in converting the kinetic energy of the wind into electrical energy in wind turbines. Here’s a detailed explanation of how electric motors are utilized in wind turbines and their role in renewable energy systems:

Wind turbines are designed to capture the energy from the wind and convert it into electrical power. Electric motors are used in wind turbines to drive the rotation of the turbine blades and generate electricity through the following process:

- Wind Capture: The wind turbine blades are designed to efficiently capture the kinetic energy of the wind. As the wind blows, it causes the blades to rotate.

- Blade Rotation: The rotational motion of the turbine blades is achieved through electric motors known as pitch motors. Pitch motors adjust the angle or pitch of the blades to optimize their orientation relative to the wind direction. The electric motors drive the mechanical mechanism that rotates the blades, allowing them to capture the maximum energy from the wind.

- Power Generation: The rotation of the wind turbine blades drives the main shaft of the turbine, which is connected to an electric generator. The generator consists of another electric motor known as the generator motor or generator rotor. The rotational motion of the generator rotor within a magnetic field induces an electrical current in the generator’s stator windings, producing electricity.

- Power Conversion and Distribution: The electricity generated by the wind turbine’s generator motor is typically in the form of alternating current (AC). To make it compatible with the electrical grid or local power system, the AC power is converted to the appropriate voltage and frequency using power electronics such as inverters. These power electronics may also incorporate electric motors for various conversion and control functions.

- Integration with Renewable Energy Systems: Wind turbines, equipped with electric motors, are integrated into renewable energy systems to contribute to the generation of clean and sustainable power. Multiple wind turbines can be connected together to form wind farms, which collectively generate significant amounts of electricity. The electricity produced by wind turbines can be fed into the electrical grid, used to power local communities, or stored in energy storage systems for later use.

Electric motors in wind turbines enable the efficient conversion of wind energy into electrical energy, making wind power a viable and renewable energy source. The advancements in motor and generator technologies, along with control systems and power electronics, have enhanced the performance, reliability, and overall efficiency of wind turbines. Additionally, electric motors allow for precise control and adjustment of the turbine blades, optimizing the energy capture and minimizing the impact of varying wind conditions.

Overall, the use of electric motors in wind turbines is instrumental in harnessing the power of wind and contributing to the generation of clean and sustainable energy in renewable energy systems.

What industries and applications commonly use electric motors?

Electric motors are widely utilized in various industries and applications due to their versatility, efficiency, and controllability. Here’s a detailed overview of the industries and applications where electric motors are commonly employed:

- Industrial Manufacturing: Electric motors are extensively used in industrial manufacturing processes. They power machinery and equipment such as conveyor systems, pumps, compressors, fans, mixers, robots, and assembly line equipment. Electric motors provide efficient and precise control over motion, making them essential for mass production and automation.

- Transportation: Electric motors play a crucial role in the transportation sector. They are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) to drive the wheels, providing propulsion. Electric motors offer benefits such as high torque at low speeds, regenerative braking, and improved energy efficiency. They are also employed in trains, trams, ships, and aircraft for various propulsion and auxiliary systems.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for air circulation, fans, blowers, and pumps. Electric motors help in maintaining comfortable indoor environments and ensure efficient cooling, heating, and ventilation in residential, commercial, and industrial buildings.

- Appliances and Household Devices: Electric motors are found in numerous household appliances and devices. They power refrigerators, washing machines, dryers, dishwashers, vacuum cleaners, blenders, food processors, air conditioners, ceiling fans, and many other appliances. Electric motors enable the necessary mechanical actions for these devices to function effectively.

- Renewable Energy: Electric motors are integral components of renewable energy systems. They are used in wind turbines to convert wind energy into electrical energy. Electric motors are also employed in solar tracking systems to orient solar panels towards the sun for optimal energy capture. Additionally, electric motors are utilized in hydroelectric power plants for controlling water flow and generating electricity.