Product Description

Product Description

- Motor Features

- Five pairs of poles, smaller volume (80% of the volume of the original 4 pairs of poles ST series motor)

- Equipped with high resolution encoder (23-bit absolute encoder)

- Maximum torque 3

M23015 M28415 M35015 M48015 Rated power (kW) 2.9 3.6 4.4 5.5 7.5 Rated torque (N.m) 18.6 23 28.4 35 48 Maximum instantaneous torque (N.m) 55.8 69 85.2 105 144 Rated speed (rpm) 1500 1500 1500 1500 1500 Maximum speed (rpm) 3000 3000 3000 3000 3000 Rated current (A) 17 24 28 38 45 Maximum instantaneous current (A) 51 72 84 114 135 Rotor inertia (kg*cm^2) 51.89 64.51 73.78 104.94 144.59 Weight(Kg)(Without brake) 15.3 17.5 19.2 25.5 32.5 Pole pairs 5 Adapted driver work voltage (VAC) 220 Insulation class F Protection level IP67 Installation type Flange mounting Environment Temperature -15~40ºC (no freezing) ,Storage temperature: -15~70ºC (no freezing) Humidity 80%RH below (no condensation) ,Storage humidity: 90%RH below (no condensation) Air Indoor (no direct sunlight), no corrosive and flammable gas, no oil mist and dust Vibration Vibration speed below 0.5mm/s LL Without brake 191 206 216 251 296 With brake 226 241 251 286 331 L1 79 79 79 113 113 L2 63 63 63 90 90 D 35 35 35 42 42 W 10 10 10 12 12 T 8 8 8 8 8 G 30 30 30 37 37 *Note: We can manufacture products according to customer’s requirements.

Motor characteristic curve

A:Continuous work area;B:Short-term work areaCompany Profile

ZheJiang KND Automation Technology CO.,Ltd

ABOUT US

ZheJiang KND CNC Technique Co.LTD(KND) was established in 1993.It is a joint-stock private enterprise that is the earliest 1 focusing on the research,production,sales and service of CNC system in China.It has the qualification of national high-tech enterprise,and it is 1 of the largest CNC system brand in China.

KND has the core technology of self-research and possesses independent intellectual property rights. After 30 years’ development, it has a number of series products: CNC system, robot controller, automation controller, feed driver and motor, spindle driver and motor, industrial Internet.These products can meet the application requirements of CNC lathes, CNC milling machines, machining centers,grinding machines and other industrial equipments.It can also be used in industrial robots, truss robots, workshop networking,data collection and analysis,and other automation fields.So,KND provided a full range of choices for different kinds of clients.

DEVELOPMENT HISTORY

PRODUCT DISTRIBUTION

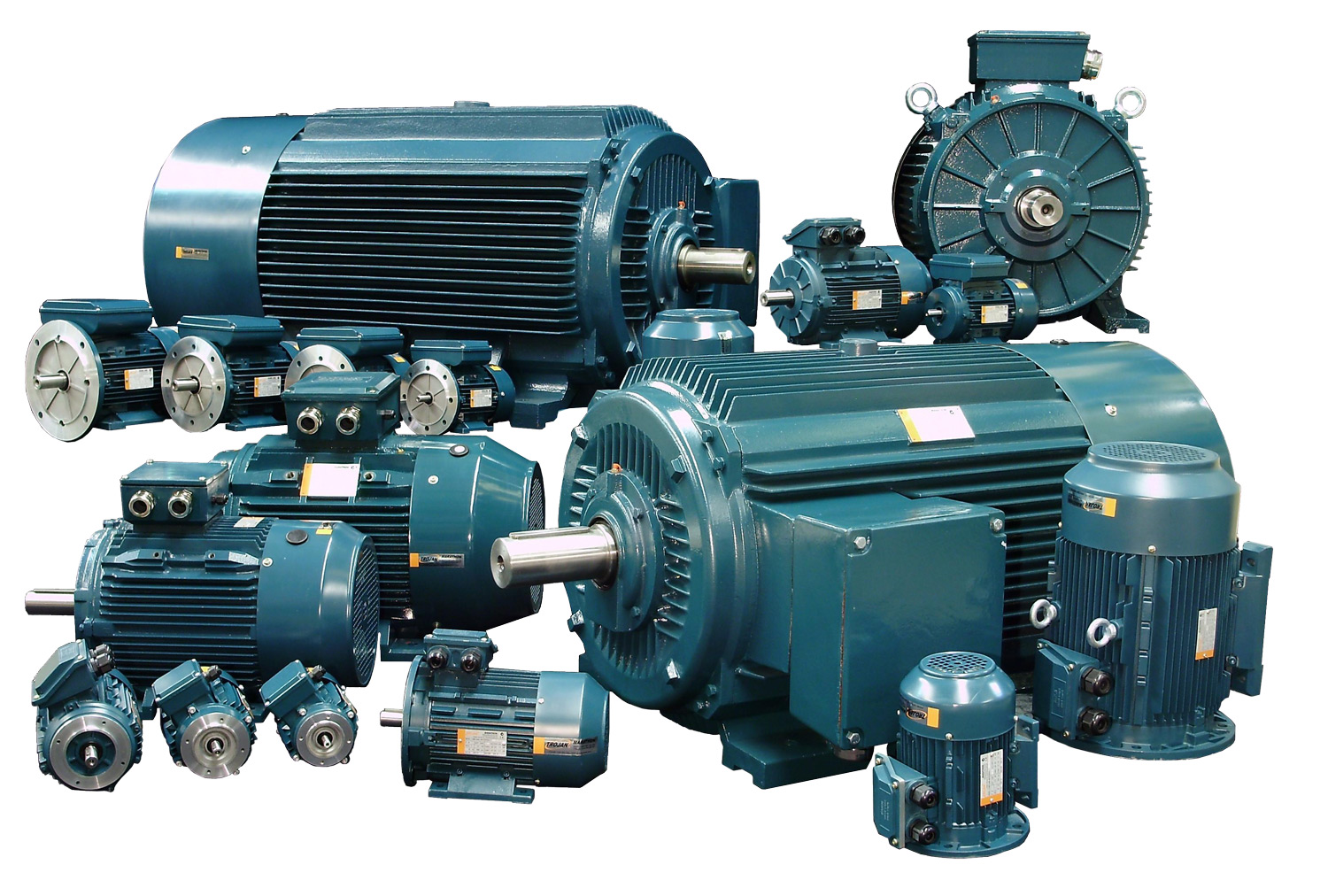

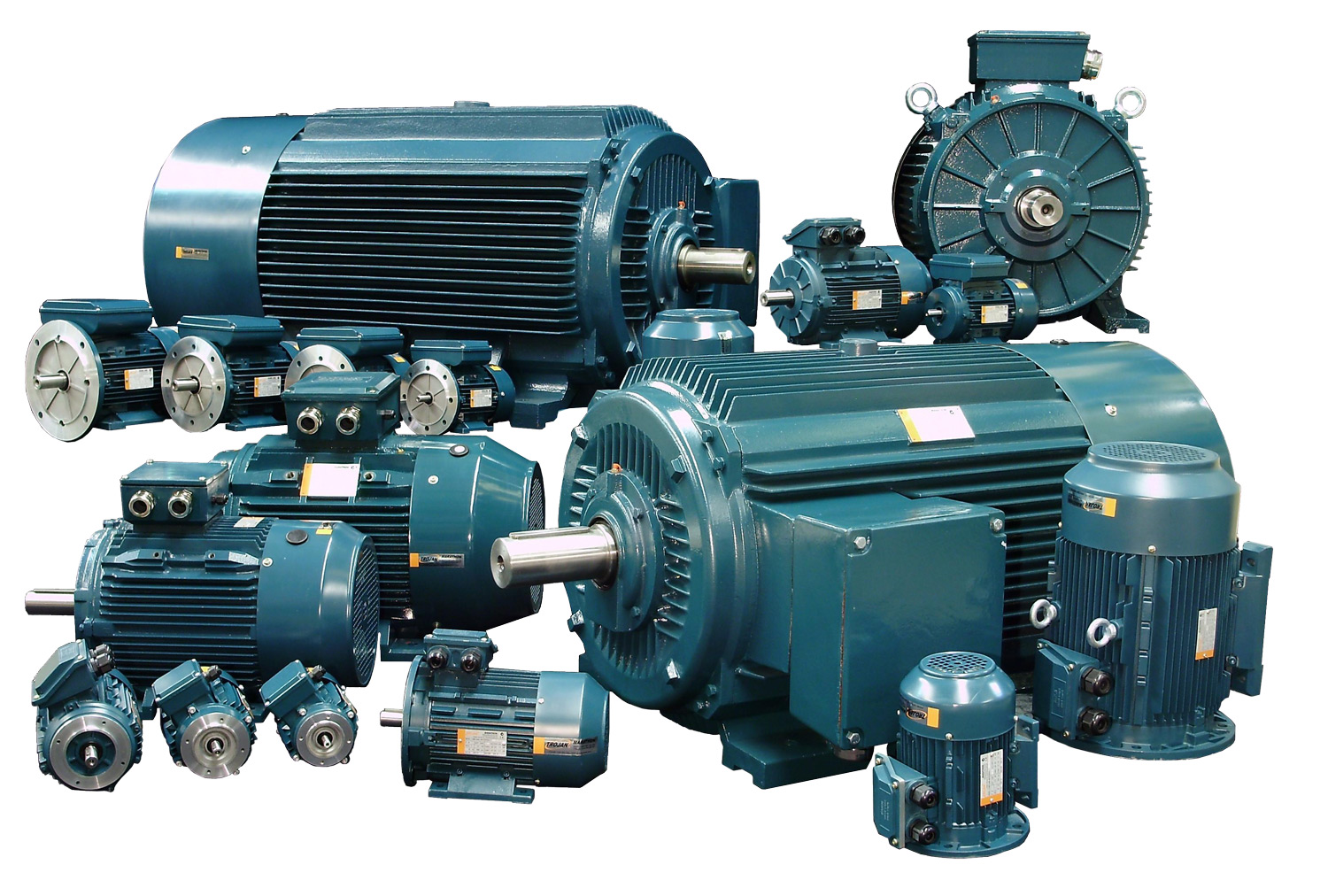

MOTOR OVERVIEW

K series synchronous servo motor is a high-performance five-pole motor developed by KND;its power ranges from 0.2kW to 7.5kW and its frame includes 60, 80, 90, 110,130, 180 series. The kind of products have the characteristics of small size, high power, high speed, better encoder configuration, and strong overload capacity.If it is used with the SD510 series driver of KND, it can make the position control come true quickly and accurately.This combination can be applied in a variety of occasions which have a higher requirements for precision control.

ZJY (-K) series AC spindle servo motor used for CNC machine tools has the characteristics of compact structure,long service life,small moment of inertia and higher control accuracy. Combined with ZD210 series of new spindle servo driver, can make its performance get better display.It can be widely used in various CNC machine tools and it can also be the spindle,feed and other parts of the CNC mechanical products.

CERTIFICATE PATENT DISPLAY

EXHIBITION

FAQ

Payments

1) We can accept EXW, FOB

2) Payment must be made before shipment.

3) Import duties, taxes and charges are not included in the item price or shipping charges. These charges are the buyer’s responsibility.Shipping

1) We only ship to your confirmed address. Please make sure your shipping address is correct before purchase.

2) Most orders will be shipped out within 3-7 working days CHINAMFG payment confirmation.

3) Shipping normally takes 7-25 working days. Most of the items will delivery in 2 weeks, while there will be a delay for something we cannot control (such as the bad weather). If it happens, just contact us, we will help you check and resolve any problem.

3) Please check the package CHINAMFG receipt, if there are some damages, please contact us immediately.

Feedback & Refund

1) Feedback is important to us, if you have any problem with our products, please contact us, our technician will give you useful advises.

2) When you have the parcel and not satisfied with the goods or it is other problem, please tell us immediately, and provide us a photo showing the detail.

3) Any reason requiring for all refund. Items must be in original condition and no physical damage. Buyer responsible for all shipping cost.If you need more information, please contact with us. We will attach great importance to your any problems.

Hope we could establish a long-term effective cooperation./* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Application: Universal, Industrial Operating Speed: Constant Speed Operation Mode: Electric Motor Magnetic Structure: Permanent Magnet Function: Driving Structure: Rotating Pole Type (Armature Fixed)

How does an electric motor ensure efficient energy conversion?

An electric motor ensures efficient energy conversion by employing various design features and principles that minimize energy losses and maximize the conversion of electrical energy into mechanical energy. Here’s a detailed explanation of how electric motors achieve efficient energy conversion:

- Efficient Motor Design: Electric motors are designed with careful consideration given to their construction and materials. High-quality magnetic materials, such as laminated iron cores and permanent magnets, are used to reduce magnetic losses and maximize magnetic field strength. Additionally, the motor’s windings are designed with low-resistance conductors to minimize electrical losses. By optimizing the motor’s design, manufacturers can improve its overall efficiency.

- Reducing Friction and Mechanical Losses: Electric motors are designed to minimize friction and mechanical losses. This is achieved through the use of high-quality bearings and lubrication systems that reduce friction between moving parts. By reducing friction, the motor can operate more efficiently, translating more of the input energy into useful mechanical work rather than dissipating it as heat.

- Efficient Control and Power Electronics: Electric motors employ advanced control techniques and power electronics to enhance energy conversion efficiency. Variable frequency drives (VFDs) are commonly used to control motor speed and torque, allowing the motor to operate at optimal efficiency levels under varying load conditions. Power electronics devices, such as insulated gate bipolar transistors (IGBTs) and MOSFETs, minimize switching losses and optimize power flow within the motor.

- Regenerative Braking and Energy Recovery: Some electric motors, particularly those used in hybrid electric vehicles (HEVs) and electric trains, incorporate regenerative braking systems. These systems convert the kinetic energy of the moving vehicle back into electrical energy, which can be stored and reused. By capturing and reusing energy that would otherwise be wasted as heat during braking, regenerative braking significantly improves overall energy efficiency.

- Efficient Cooling and Thermal Management: Electric motors generate heat during operation, and excessive heat can lead to energy losses and reduced efficiency. To mitigate this, motors are designed with efficient cooling systems such as fans, heat sinks, or liquid cooling methods. Proper thermal management ensures that the motor operates within the optimal temperature range, reducing losses and improving overall efficiency.

- High-Efficiency Standards and Regulations: Governments and organizations have established energy efficiency standards and regulations for electric motors. These standards encourage manufacturers to produce motors with higher efficiency ratings. Compliance with these standards ensures that motors meet certain efficiency criteria, resulting in improved energy conversion and reduced energy consumption.

By incorporating these design features, control techniques, and efficiency measures, electric motors achieve efficient energy conversion. They minimize energy losses due to factors such as resistance, friction, and heat dissipation, ensuring that a significant portion of the input electrical energy is converted into useful mechanical work. The continuous advancements in motor design, materials, and control technologies further contribute to improving the overall energy efficiency of electric motors.

Can electric motors be used in renewable energy systems like wind turbines?

Yes, electric motors can be used in renewable energy systems like wind turbines. In fact, electric motors play a crucial role in converting the kinetic energy of the wind into electrical energy in wind turbines. Here’s a detailed explanation of how electric motors are utilized in wind turbines and their role in renewable energy systems:

Wind turbines are designed to capture the energy from the wind and convert it into electrical power. Electric motors are used in wind turbines to drive the rotation of the turbine blades and generate electricity through the following process:

- Wind Capture: The wind turbine blades are designed to efficiently capture the kinetic energy of the wind. As the wind blows, it causes the blades to rotate.

- Blade Rotation: The rotational motion of the turbine blades is achieved through electric motors known as pitch motors. Pitch motors adjust the angle or pitch of the blades to optimize their orientation relative to the wind direction. The electric motors drive the mechanical mechanism that rotates the blades, allowing them to capture the maximum energy from the wind.

- Power Generation: The rotation of the wind turbine blades drives the main shaft of the turbine, which is connected to an electric generator. The generator consists of another electric motor known as the generator motor or generator rotor. The rotational motion of the generator rotor within a magnetic field induces an electrical current in the generator’s stator windings, producing electricity.

- Power Conversion and Distribution: The electricity generated by the wind turbine’s generator motor is typically in the form of alternating current (AC). To make it compatible with the electrical grid or local power system, the AC power is converted to the appropriate voltage and frequency using power electronics such as inverters. These power electronics may also incorporate electric motors for various conversion and control functions.

- Integration with Renewable Energy Systems: Wind turbines, equipped with electric motors, are integrated into renewable energy systems to contribute to the generation of clean and sustainable power. Multiple wind turbines can be connected together to form wind farms, which collectively generate significant amounts of electricity. The electricity produced by wind turbines can be fed into the electrical grid, used to power local communities, or stored in energy storage systems for later use.

Electric motors in wind turbines enable the efficient conversion of wind energy into electrical energy, making wind power a viable and renewable energy source. The advancements in motor and generator technologies, along with control systems and power electronics, have enhanced the performance, reliability, and overall efficiency of wind turbines. Additionally, electric motors allow for precise control and adjustment of the turbine blades, optimizing the energy capture and minimizing the impact of varying wind conditions.

Overall, the use of electric motors in wind turbines is instrumental in harnessing the power of wind and contributing to the generation of clean and sustainable energy in renewable energy systems.

What are the different types of electric motors available?

There are various types of electric motors available, each designed for specific applications and operating principles. These motors differ in their construction, power sources, and performance characteristics. Here is an overview of some common types of electric motors:

- DC Motors: DC (Direct Current) motors are widely used and come in different configurations. The most common types include brushed DC motors and brushless DC motors. Brushed DC motors use brushes and a commutator to switch the direction of current in the rotor, while brushless DC motors use electronic commutation. DC motors offer good speed control and torque characteristics, making them suitable for applications like robotics, electric vehicles, and small appliances.

- AC Motors: AC (Alternating Current) motors are classified into several types, including induction motors, synchronous motors, and universal motors. Induction motors are popular for their simplicity and reliability. They operate based on electromagnetic induction and are commonly used in industrial and residential applications. Synchronous motors operate at a constant speed and are often used in applications that require precise control, such as industrial machinery and synchronous clocks. Universal motors are designed to operate on both AC and DC power sources and are commonly found in household appliances like vacuum cleaners and power tools.

- Stepper Motors: Stepper motors are designed to move in discrete steps or increments, making them suitable for applications that require precise positioning. They are often used in robotics, 3D printers, CNC machines, and other automated systems. Stepper motors are available in various configurations, including permanent magnet stepper motors, variable reluctance stepper motors, and hybrid stepper motors.

- Servo Motors: Servo motors are a type of motor that combines a DC motor with a feedback control mechanism. They are known for their precise control over position, velocity, and acceleration. Servo motors are commonly used in robotics, industrial automation, and applications that require accurate motion control, such as robotic arms, RC vehicles, and camera gimbals.

- Linear Motors: Linear motors are designed to produce linear motion instead of rotational motion. They operate on similar principles as rotary motors but with a different mechanical arrangement. Linear motors find applications in high-speed transportation systems, cutting machines, and other systems that require linear motion without the need for mechanical conversion from rotary to linear motion.

- Haptic Motors: Haptic motors, also known as vibration motors, are small motors used to create tactile feedback or vibrations in electronic devices. They are commonly found in smartphones, game controllers, wearable devices, and other gadgets that require haptic feedback to enhance the user experience.

These are just a few examples of the different types of electric motors available. Each type has its own advantages, limitations, and specific applications. The selection of an electric motor depends on factors such as the required torque, speed, control, efficiency, and the specific needs of the application at hand.

editor by CX 2023-12-28